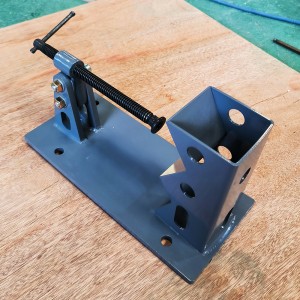

Welding bakin karfe tebur Frames wani muhimmin tsari ne wanda ke buƙatar ilimin ƙwararru da ƙwarewa.Bakin karfe kayan ƙarfe ne mai jure lalata, don haka ana buƙatar kulawa ta musamman yayin aikin walda don tabbatar da inganci da karko na haɗin gwiwa.

Na farko, zabar hanyar walda mai kyau yana da mahimmanci.Don firam ɗin tebur na bakin ƙarfe, TIG (argon arc waldi) ko MIG (ƙarfe inert gas waldi) ana amfani da hanyoyin walda.waldi na TIG ya dace da lokatai tare da buƙatu mafi girma akan bayyanar walda da inganci, yayin da walda MIG ya dace da lokatai tare da buƙatu masu girma akan ingantaccen samarwa.

Abu na biyu, zabar kayan walda masu dacewa shima yana da matukar muhimmanci.Bakin karfe firam ɗin tebur gabaɗaya ana welded tare da bakin karfe wayoyi na abu ɗaya ko makamancin haka.Wannan yana tabbatar da cewa haɗin gwiwar welded yana da irin wannan kaddarorin da juriya na lalata ga ƙarfe na tushe.

Kafin waldawa, welded gidajen abinci da tushe karfe bukatar da za a cikakken tsabtace da pretreated don cire surface datti da oxides da kuma tabbatar da walda ingancin.A lokaci guda kuma, yayin aikin walda, ana buƙatar sarrafa ƙarfin walda, ƙarfin lantarki da saurin walda don sanya haɗin gwiwar walda ɗin su zama daidai kuma ya tabbata.

A ƙarshe, bayan an gama waldawar, haɗin haɗin da aka haɗa yana buƙatar aiwatarwa bayan aiwatarwa, kamar niƙa, goge goge, da sauransu, don haɓaka kyawun kamanni.

A takaice, walda bakin karfe Frames na bukatar m la'akari da mahara dalilai kamar abu selection, waldi hanyoyin, pre-jiyya da bayan-jiyya don tabbatar da inganci da karko na welded gidajen abinci.

Lokacin aikawa: Maris-06-2024