Hana wiliwili i nā ʻāpana metala kuhili ʻole

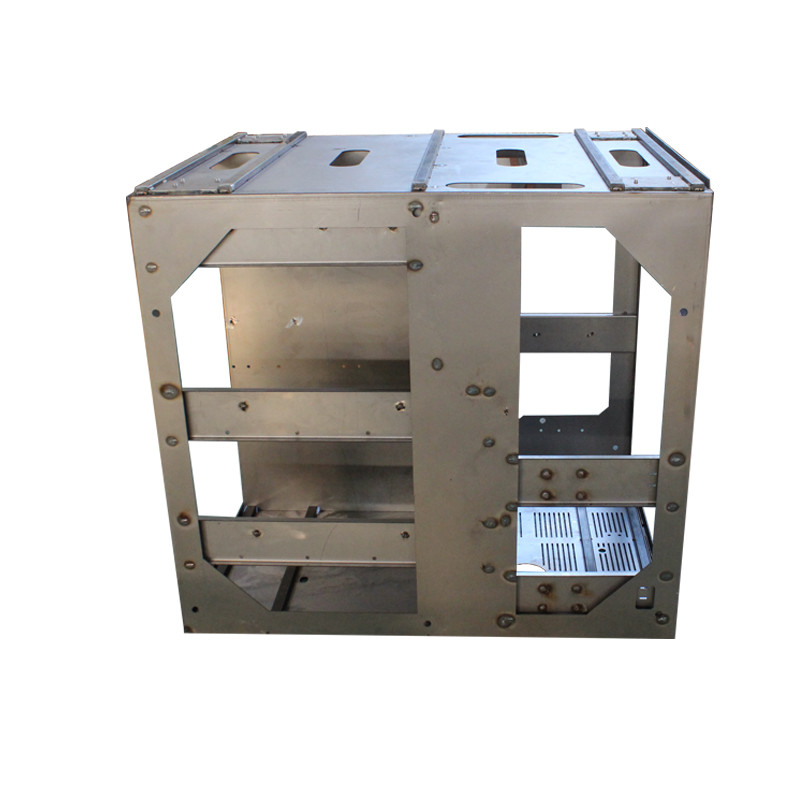

Hōʻike huahana

Kuʻi kūʻē

ʻO ke kuʻekuʻe kūʻē he ʻano kuʻikuʻi kahi e hui ʻia ai ka mea hana a hoʻopili ʻia ke kaomi ma o ka electrode, a hoʻohana ʻia ke ʻano uila ma o ka wela kūpaʻa i hana ʻia e ka ʻili pili a me nā wahi pili o ka hui.ʻO ke kuʻi kūʻē ʻana he ala ia e hoʻomehana ai i ka mea hana i kahi ʻano hoʻoheheʻe a i ʻole ka plastik e ka uila e kahe ana ma ka ʻili pili a me nā wahi pili.ʻEhā mau ʻano hana kuʻi kūʻē nui, ʻo ia hoʻi ka wiliwili wahi, ka wili wili, ka wili projection a me ka wili kī.

Kuʻi kalapona kalapona

ʻO ke kinoea pale o ka hoʻoheheʻe kalapona kalapona ka carbon dioxide (i kekahi manawa he hui ʻana o CO2+Ar).Hoʻohana nui ʻia no ka welding manual.Ma muli o ka mana kūikawā o nā waiwai kino wela o ke kinoea kalapona, i ka wā e hoʻohana ai i ka mana kuʻihao maʻamau, ʻaʻole hiki ke hana i kahi hoʻololi axial manuahi ʻole ma ka hoʻoheheʻe ʻana i ka metala ma ka hopena uwea welding, ka mea maʻamau e koi i ka pōkole pōkole a me ka droplet necking. pahū.No laila, ke hoʻohālikelike ʻia me ka MIG welding free transition, ʻoi aku ka nui o ka splash.Akā inā hiki ke hoʻohana ʻia ka mīkini wili kiʻekiʻe, ke koho kūpono o nā ʻāpana, hiki ke loaʻa i kahi kaʻina hana kuʻi paʻa, i hoʻemi ʻia ka spatter i kahi liʻiliʻi.Ma muli o ke kumu kūʻai haʻahaʻa o ke kinoea pale i hoʻohana ʻia, ua hana maikaʻi ʻia ka weld i ka wā e hoʻohana ai i ka hoʻololi kaapuni pōkole, i hui pū ʻia me ka hoʻohana ʻana i ka uea i loaʻa ka deoxidizer hiki ke loaʻa me ka ʻole o nā hemahema o loko o ka hui kuʻi maikaʻi.No laila, ua lilo kēia ʻano hoʻoheheʻe i kekahi o nā ʻano hana wili koʻikoʻi no nā mea metala ferrous.

Argon arc welding

ʻO Argon arc welding kahi ʻenehana wiliwili e hoʻohana ana i ke kinoea argon ma ke ʻano he kinoea pale.ʻIke pū ʻia ʻo ka welding pale kino argon.ʻO ia ke hele ʻana i ke kinoea pale argon a puni ka wili arc e hoʻokaʻawale i ka ea ma waho o ka wahi wili a pale i ka oxidation o ka wahi wili.

ʻO Argon arc welding ʻenehana ma ke kumu o ke kumu o ka wiliwili uila maʻamau, me ka hoʻohana ʻana i ka pale kinoea argon no nā mea hoʻoheheʻe metala, ma o ke kiʻekiʻe o kēia manawa ma ka welding backing weld material e hoʻoheheʻe ʻia i loko o kahi wai wai wai, kumu i ka weld metala a me nā mea weld. metallurgy i hui pū me ke ʻano o ka ʻenehana welding, i ke kiʻekiʻe o ka wela hoʻoheheʻe ʻana ma ka argon mau, e hana i ka weld mea ʻaʻole hiki ke hoʻopili me ka oxygen i ka lewa, pēlā e pale ai i ka oxidation o ka welding mea, no laila hiki iā ʻoe ke weld stainless steel, hao hao.

Hoʻopili laser

Hiki ke hoʻokō ʻia ka hoʻoheheʻe ʻana i ka laser me ka hoʻomau a i ʻole pulsed laser beam.Hiki ke hoʻokaʻawale ʻia ke kumu o ka welding laser i ka welding conduction wela a me ka welding fusion hohonu laser.Ke emi ka mana o ka mana ma mua o 10-10 W / cm, ʻo ia ka wela conduction welding, a lohi ka hohonu o ka welding a me ka wikiwiki.Ke ʻoi aku ka nui o ka mana ma mua o 10 ~ 10 W / cm, ua concave ka ʻili metala i loko o nā "puka" ma lalo o ka hana o ka wela, e hana ana i ka fusion fusion hohonu, nona nā ʻano o ka wikiwiki welding wikiwiki a me ka nui o ka hohonu a me ka laulā.

ʻO ke kumu o ka welding laser conduction wela: hoʻomaʻamaʻa ka radiation laser i ka ʻili e hoʻoponopono ʻia, a hoʻoheheʻe ka wela o ka ʻili i loko ma o ka hoʻokele wela.Ma ka hoʻomalu ʻana i nā ʻāpana laser e like me ka laulā, ka ikehu, ka mana kiʻekiʻe a me ka hana pinepine ʻana o ka pulse laser, hoʻoheheʻe ʻia ka mea hana a hoʻokumu ʻia kahi wai hoʻoheheʻe kikoʻī.

ʻO Lambert sheet metal custom processing solutions provider.

Me nā makahiki he ʻumi o ka ʻike ma ke kālepa ʻana i nā ʻāina ʻē, ʻoihana mākou i nā ʻāpana hoʻoheheʻe metala kiʻekiʻe, ka ʻoki ʻana i ka laser, ke kuʻi ʻana o ka metala, nā pale metala, nā ʻāpana metala chassis, nā hale hoʻolako mana chassis, a me nā mea ʻē aʻe. , polishing, sandblasting, spraying, plating, hiki ke hoʻohanaʻia i nā hoʻolālā kālepa, nā awa, nā alahaka, nā hale hana, nā hale, nā hōkele, nā pūnaewele paipu likeʻole, a me nā mea'ē aʻe. maikaʻi a maikaʻi hoʻi nā lawelawe hana i kā mākou mea kūʻai.Hiki iā mākou ke hana i nā ʻāpana metala o nā ʻano like ʻole e hoʻokō i nā pono mīkini piha o kā mākou mea kūʻai.Ke hoʻomau nei mākou i ka hana hou a me ka hoʻonui ʻana i kā mākou mau kaʻina hana e hōʻoia i ka maikaʻi a me ka lawe ʻana, a ʻo mākou ka "mea kūʻai aku" e hāʻawi i kā mākou mea kūʻai aku i ka lawelawe maikaʻi a kōkua iā lākou e hoʻokō i ka kūleʻa.Manaʻo mākou e kūkulu i nā pilina lōʻihi me kā mākou mea kūʻai aku ma nā wahi āpau!