Kev cai Stainless hlau hlau qhov chaw vuam Service

Product Description

Kuj welding

Resistance welding yog ib txoj kev vuam uas cov khoom ua haujlwm sib xyaw ua ke thiab lub zog yog siv los ntawm cov electrode, thiab cov hluav taws xob tam sim no yog siv los ntawm cov hluav taws xob tiv thaiv los ntawm kev sib cuag ntawm qhov chaw thiab qhov chaw nyob ib sab ntawm qhov sib koom ua ke.Resistance welding yog ib txoj hauv kev ua kom sov lub workpiece mus rau lub xeev molten los yog yas los ntawm cov hluav taws xob tam sim no ntws los ntawm qhov chaw sib cuag thiab cov chaw nyob ib sab.Muaj plaub qhov tseem ceeb ntawm kev siv vuam, uas yog qhov chaw vuam, seam vuam, qhov projection vuam thiab taub qab vuam.

Carbon dioxide vuam

Lub shielding gas ntawm carbon dioxide arc vuam yog carbon dioxide (qee zaum sib tov ntawm CO2 + Ar).Feem ntau yog siv rau kev tuav vuam.Vim tias muaj kev cuam tshuam tshwj xeeb ntawm cov khoom siv hluav taws xob thermal ntawm cov pa roj carbon dioxide, thaum siv cov khoom siv hluav taws xob zoo sib xws, nws tsis tuaj yeem tsim kom muaj kev hloov pauv axial dawb los ntawm melting cov hlau ntawm vuam hlau kawg, uas feem ntau yuav tsum tau luv luv Circuit Court thiab droplet necking. tawg.Yog li ntawd, piv nrog MIG vuam dawb hloov pauv, muaj ntau txaws.Tab sis yog tias kev siv lub tshuab vuam zoo, qhov kev xaiv ntawm qhov tsis zoo, tuaj yeem tau txais cov txheej txheem vuam ruaj khov heev, kom cov spatter raug txo kom tsawg.Vim tias tus nqi qis ntawm kev tiv thaiv roj siv, cov vuam yog tsim tau zoo thaum siv luv luv Circuit Court hloov, ua ke nrog kev siv cov hlau uas muaj deoxidizer tuaj yeem tau txais yam tsis muaj qhov tsis xws luag ntawm kev sib txuas zoo.Yog li ntawd, txoj kev vuam no tau dhau los ua ib txoj hauv kev tseem ceeb tshaj plaws rau cov khoom siv hlau ferrous.

Argon arc vuam

Argon arc welding yog vuam tshuab siv cov roj argon ua cov roj tiv thaiv.Kuj tseem hu ua argon lub cev tiv thaiv vuam.Nws yog kom dhau argon tiv thaiv roj nyob ib ncig ntawm lub arc vuam kom cais cov huab cua sab nraum lub vuam cheeb tsam thiab tiv thaiv oxidation ntawm vuam cheeb tsam.

Argon arc vuam tshuab yog nyob rau hauv lub hauv paus ntsiab lus ntawm kev siv hluav taws xob arc vuam, siv cov argon roj tiv thaiv rau cov hlau vuam cov ntaub ntawv, los ntawm cov tam sim no siab ntawm vuam backing weld cov ntaub ntawv yaj mus rau hauv lub pas dej ua kua, ua rau cov hlau weld thiab weld khoom. metallurgy ua ke nrog ib hom vuam tshuab, nyob rau hauv kub melting vuam ntawm argon tas li, ua rau cov khoom weld tsis tuaj yeem tiv tauj nrog oxygen hauv huab cua, Yog li tiv thaiv oxidation ntawm cov khoom siv vuam, yog li koj tuaj yeem vuam stainless hlau, hlau hlau.

Laser vuam

Laser vuam tuaj yeem pom tau los ntawm kev nruam lossis lub teeb ci laser.Lub hauv paus ntsiab lus ntawm laser vuam yuav muab faib ua cua sov conduction vuam thiab laser sib sib zog nqus fusion vuam.Thaum lub zog ceev yog tsawg dua 10-10 W / cm, nws yog cov cua sov conduction vuam, thiab vuam qhov tob thiab vuam ceev yog qeeb.Thaum lub zog ceev yog ntau dua 10 ~ 10 w / cm, lub hlau nto yog concave ua kom sov, uas muaj cov yam ntxwv sib sib zog nqus vuam, uas muaj cov yam ntxwv ntawm qhov tob vuam ceev thiab loj piv rau dav.

Lub hauv paus ntsiab lus ntawm tshav kub conduction laser vuam yog: lub laser hluav taws xob heats lub nto yuav tsum tau ua, thiab saum npoo tshav kub diffuses sab hauv los ntawm tshav kub conduction.Los ntawm kev tswj cov laser tsis xws li qhov dav, lub zog, lub zog siab tshaj plaws thiab rov ua dua zaus ntawm lub laser pulse, lub workpiece yog melted thiab ib tug tshwj xeeb molten pas dej ua ke yog tsim.

Lambert sheet hlau kev cai kev daws teeb meem muab kev pab.

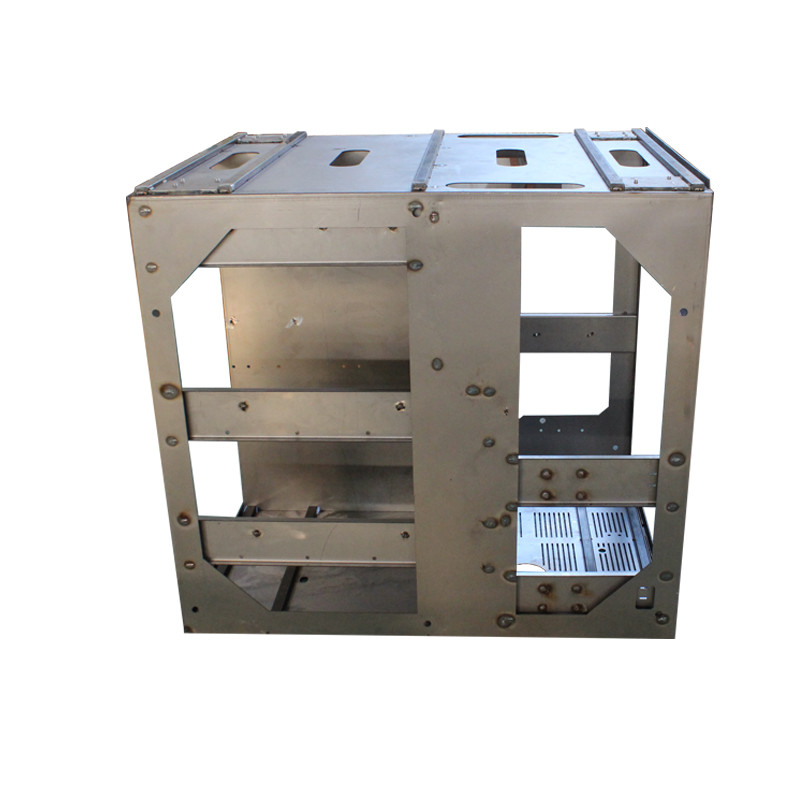

Nrog kaum xyoo ntawm kev paub nyob rau hauv txawv teb chaws kev lag luam, peb tshwj xeeb nyob rau hauv high precision sheet hlau ua qhov chaw, laser txiav, sheet hlau dabtsi yog khoov, hlau brackets, sheet hlau chassis shells, chassis fais fab mov vaj tse, thiab lwm yam. Peb paub ntau yam kev kho deg, txhuam , polishing, sandblasting, txau, plating, uas tuaj yeem siv rau kev lag luam tsim, chaw nres nkoj, txuas hniav, infrastructure, tsev, tsev so, ntau yam piping systems, thiab lwm yam. Peb muaj cov cuab yeej ua haujlwm siab heev thiab pab pawg tshaj lij tshaj lij ntawm 60 tus neeg los muab siab. kev ua haujlwm zoo thiab ua haujlwm zoo rau peb cov neeg siv khoom.Peb muaj peev xwm tsim cov ntawv hlau ntawm ntau cov duab kom tau raws li peb cov neeg siv khoom tiav machining xav tau.Peb tab tom tsim kho tshiab thiab ua kom zoo dua peb cov txheej txheem kom ua tau zoo thiab xa khoom, thiab peb ib txwm "cov neeg siv khoom tsom" los muab peb cov neeg siv khoom zoo thiab pab lawv ua tiav.Peb tos ntsoov yuav tsim kev sib raug zoo nrog peb cov neeg siv khoom nyob rau hauv txhua qhov chaw!