laser cutting service

-

OEM customised stainless steel sheet metal box

Specialising in bespoke sheet metal boxes, we create high quality, personalised products with our superb sheet metal workmanship. Whether it’s size, shape or material, all can be tailored to your needs. Our attention to detail and pursuit of excellence ensures that every sheet metal box meets your expectations.

-

Customized industry first class metal stainless steel table leg supports

The Process of Customized Sheet Metal Fabrication Explained

The process of customized sheet metal processing usually includes the following key steps:

Demand analysis: first, in-depth communication with the customer to clarify the specific needs of the electrical box enclosure, such as size, shape, material, color and so on.

Design Drawing: According to customer needs, designers utilize CAD and other design software to draw accurate 3D drawings to ensure that every detail meets customer requirements.

Material selection: According to the design requirements and usage, choose the suitable metal sheet, such as stainless steel, aluminum alloy, etc.

Cutting and processing: Using high-precision equipment such as laser cutting machine or waterjet cutting machine, the metal sheet is cut into the required shape according to the drawings.

Bending and molding: The cut sheet is bent by bending machine to form the required three-dimensional structure.

Welding and assembly: Welding process is used to connect the parts together to form a complete electrical box shell.

Surface treatment: Surface treatment of the enclosure, such as spraying, sandblasting, anodizing, etc., to increase its aesthetics and durability.

Quality Inspection: Strict quality inspection is carried out to ensure that the size, structure and appearance of the electrical box shell meet the customer’s requirements.

Packing and shipping: Finally, packaging and shipping to customers.

The whole process pays attention to details and quality to ensure that the final product can meet the various needs of customers.

-

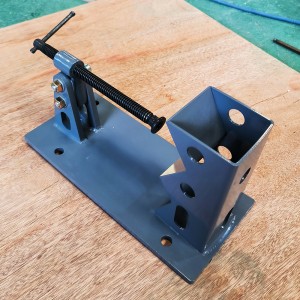

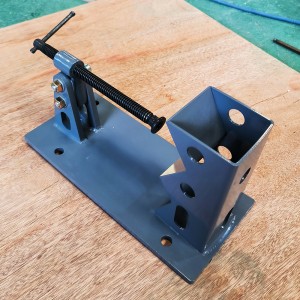

OEM custom metal electronic fixture welding processing

We specialise in custom sheet metal processing with advanced welding technology and precision metal electronic fixtures. The fixtures are reasonably designed and have a stable structure, which ensures processing accuracy and efficiency. The welding process is exquisite, with beautiful weld seams and high strength.

-

OEM Customised Metal Products Sheet Metal Welding

Laser cutting, leading technology, precise and fast, cutting the plate into the required shape. Welding process, firm and stable, makes the parts perfectly fused. We provide one-stop laser cutting and welding services, offering solutions for customised processing of various plates.

-

OEM custom sheet metal fabrication parts laser cutting

Steel structure, strong and durable, we focus on sheet metal custom processing, choose high quality stainless steel materials, carefully build each steel frame. Exquisite craftsmanship, strict quality control, to ensure that each product meets your needs.

-

Custom Laser Cutting Plate Welding Metal Services

Laser cutting, precision, instant separation of steel plates, showing the fine craftsmanship of customised sheet metal processing. Seamless welding, metal fusion, constructing a solid beauty. We focus on sheet metal customisation, with laser cutting and metal welding skills, to create excellent quality for you.

-

OEM customised metal processing laser cut parts

Laser cutting, with the precision of a laser, our laser cutting technology can easily cope with a variety of complex patterns and structures, ensuring that every piece of metalwork is precise and accurate. Choose us to give your custom sheet metal processing project a new look, with quality and beauty.

-

OEM ODM Factory Customized Laser Cut Stainless Steel Sheet Metal Shell

Sheet metal processing: the professional choice for customized electrical box enclosures

Sheet metal processing plays an important role in many industries, especially in the customization of electrical box enclosure to show its unique advantages. As an important structure to protect the internal electrical components, the quality of the enclosure is directly related to the safe and stable operation of the equipment.

When customizing the enclosure of an electrical box, sheet metal processing ensures the accuracy and robustness of the enclosure through precise laser cutting, high-quality bending and solid welding processes. In addition, the customized design makes the electrical box enclosure not only meet the functional requirements, but also harmonize with the overall equipment style to enhance the overall aesthetics.

With rich experience and advanced technical equipment in sheet metal processing, China Factory is capable of meeting various complex and delicate processing requirements. Choosing China factories for the customization of electrical box enclosures means not only getting high quality products, but also enjoying efficient services and reasonable prices.

All in all, sheet metal processing shows its unique advantages and professionalism in customized electrical box enclosure, which is another highlight of China factories in the field of manufacturing.

-

Custom large stainless steel metal engineered funnel supports

Build metal engineering funnel bracket, choose high quality metal materials, combined with exquisite sheet metal technology, to ensure that the bracket is sturdy and durable, strong load-bearing capacity. Unique design, so that the funnel placed firmly, smooth drainage. Personalised to meet your different engineering needs.

-

OEM Custom Sheet Metal Processing Laser Cutting Parts

Adopting high-precision laser cutting technology to ensure that the size of each part is precise and accurate. Combined with rich experience in sheet metal processing, we can create sturdy and durable parts for you. Professional customisation to meet your various needs and inject quality and creativity into your projects.

-

Customised outdoor waterproof stainless steel dog bowl

We specialise in customised outdoor waterproof stainless steel dog bowl, made of durable stainless steel, combined with exquisite sheet metal workmanship to create a sturdy and durable dog bowl. The unique waterproof design ensures a dry and clean environment for your pet’s meal.

-

Custom Metal Welding Projects Stainless Steel Sheet Metal Fabrication Components

The Process of Customized Sheet Metal Fabrication Explained

The process of customized sheet metal processing usually includes the following key steps:

Demand analysis: first, in-depth communication with the customer to clarify the specific needs of the electrical box enclosure, such as size, shape, material, color and so on.

Design Drawing: According to customer needs, designers utilize CAD and other design software to draw accurate 3D drawings to ensure that every detail meets customer requirements.

Material selection: According to the design requirements and usage, choose the suitable metal sheet, such as stainless steel, aluminum alloy, etc.

Cutting and processing: Using high-precision equipment such as laser cutting machine or waterjet cutting machine, the metal sheet is cut into the required shape according to the drawings.

Bending and molding: The cut sheet is bent by bending machine to form the required three-dimensional structure.

Welding and assembly: Welding process is used to connect the parts together to form a complete electrical box shell.

Surface treatment: Surface treatment of the enclosure, such as spraying, sandblasting, anodizing, etc., to increase its aesthetics and durability.

Quality Inspection: Strict quality inspection is carried out to ensure that the size, structure and appearance of the electrical box shell meet the customer’s requirements.

Packing and shipping: Finally, packaging and shipping to customers.

The whole process pays attention to details and quality to ensure that the final product can meet the various needs of customers.