laser cutting service

-

china manufacture custom processing metal sheet parts

Let’s learn about laser cutting and molding technology. Laser cutting is a process that utilizes a high-energy laser beam to cut sheet metal materials into specific shapes. By controlling the focus and intensity of the laser beam, precise and fast cutting can be realized. Compared with traditional mechanical cutting methods, laser cutting has the following advantages:

High precision: Laser cutting can achieve more precise shapes and sizes, whether it is a simple straight line or a complex curve.

Fast: Laser cutting is fast, which can greatly improve the production efficiency, especially suitable for mass production.

Flexibility: Laser cutting can handle a wide variety of materials, including steel, aluminum, stainless steel, and more. It can also cut sheet metal materials of various thicknesses, enabling the customization of a wide range of products.

-

First Class Sheet Metal Fence Post Manufacturer

Sheet metal custom metal railings play an important role in the construction industry. Sheet metal custom railings offer many advantages over traditional railings. First of all, sheet metal custom railings can be designed and customized according to customer needs, making them perfectly blend with the architectural style. Secondly, sheet metal custom railings are made of high-quality metal materials with excellent durability and strength to ensure safety and reliability. In addition, customized railings can also add various decorative elements according to needs, such as patterns, patterns, etc., to increase the aesthetics of the building. Overall, sheet metal custom metal railings are a functional, aesthetically pleasing option that add a unique charm to a building.

-

OEM Customized Heavy Metal Stainless Steel Cutting & steel bracket

OEM Customized Heavy Metal Stainless Steel Cutting & steel bracket / Sheet Metal Fabrication Semi-finished Product Service

-

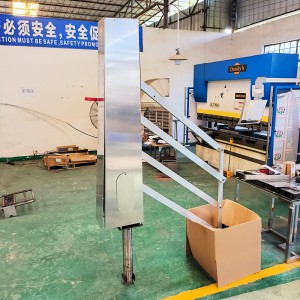

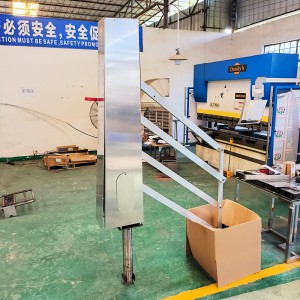

OEM Customized Stainless Steel Safe Metal Cabinet semi-finished

A customized safe with sheet metal processing is a manufactured security storage device used to protect valuables and documents.

-

OEM custom metal fabrication stainless steel foldable molded products

Customized stainless steel cart is a common logistics and transportation equipment, widely used in factories, warehouses, supermarkets and other places. It is made of stainless steel material with corrosion resistance, abrasion resistance and sturdy structure, which can meet the material handling needs in various environments

-

Customized Large Metal Cage Fabrication Manufacturer

Large metal frame fabrication usually involves the use of thicker metal sheets, such as steel and aluminum, to create frame structures with load-bearing capabilities. These frames are commonly used in industries such as construction, aerospace and automotive manufacturing, where they play an important role in support and protection

-

Popular custom sheet metal laser cut bracket parts

The advantages of sheet metal laser cutting and forming mainly include:

High precision: laser cutting can achieve high-precision cutting, small error, stable and reliable processing quality.

High efficiency: laser cutting speed, can quickly cut various shapes of sheet metal, improve production efficiency.

Can cut complex shapes: laser cutting can cut metal sheets of various complex shapes, such as round, arc, irregular shapes, etc., to meet a variety of different processing needs.

Good quality of cut: the cut of laser cutting is flat and smooth, no need for post-processing such as grinding, which saves cost and time.

Environmental protection: the laser cutting process does not produce any waste, exhaust and other pollution, it is an environmentally friendly processing method. -

OEM custom processing 1-6mm metal laser cutting parts forming service

Sheet metal laser cutting is a highly efficient, precise, time and labor-saving cutting process that can cut parts of various shapes and sizes from thin sheet materials. It works by using a high-energy laser beam to irradiate on the surface of the material, causing the material to rapidly melt, vaporize or reach the ignition point, and at the same time blowing away the melted or burned portion of the material with a high-speed airflow to achieve cutting. Compared with the traditional cutting methods, sheet metal laser cutting has the advantages of high precision, high efficiency, easy operation, etc. It can cut very fine patterns and shapes, and the cutting speed is very fast, so that a large amount of material can be cut in a short time. Sheet metal laser cutting has a wide range of applications, such as automotive, electronics, aerospace, medical and other industries where it can be found.

-

OEM Customized Precision Laser Cutting and Bending Stainless Steel Metal Case

With the development of technology, the demand for customization of sheet metal enclosures is becoming more and more diversified. Laser cutting opening and bending is an important process technology to realize this goal. Laser cutting can accurately cut out various shapes, and the edges of openings are neat and burr-free, which can greatly improve work efficiency. Sheet metal bending, on the other hand, can bend two-dimensional flat sheets into three-dimensional shapes at specified angles and lengths, with high molding precision and seamless docking. Through the combination of these two processes, we are able to customize both beautiful and practical sheet metal enclosures to meet a variety of different needs.

-

OEM custom metal tube manufacturing with holes for stainless steel carbon steel laser cutting services

Our team will provide you with professional cutting suggestions and solutions based on your design drawings or actual needs to ensure the accuracy and perfection of the production. By choosing us, you will receive high-quality, professional sheet metal laser cutting services that will open up unlimited possibilities for your innovative designs and fabrications. Let’s create excellence together and add unlimited possibilities to your designs.

-

OEM steel structure design metal fabrication welding custom metal processing with laser cutting stainless steel table frame

We use high-quality stainless steel materials, through fine sheet metal processing and polishing, to create a strong, durable and beautiful table frame. You can choose different styles, sizes and colours to suit different desktop sizes and needs.

-

OEM custom metal sheet bending stainless steel metal laser cutting parts service stainless steel welding parts enclosure

We use advanced laser cutting technology to accurately cut sheet metal parts of various shapes and sizes, whether it’s hollowing, gouging or complex patterns, we can meet your needs!