Sheet metal frame customization

-

Customized Large Outdoor Rustproof Metal Livestock Iron Fence/3d metal cutting/3d metal design

Customized sheet metal processing is a processing method tailored to customer needs. It can meet customer needs for sheet metal products of specific shapes, sizes and materials. The sheet metal custom processing process usually includes the following steps:

1. Confirmation of customer requirements: First, customers need to provide detailed sheet metal product requirements, including size, shape, material requirements, etc. This information will form the basis for custom processing, ensuring the final product meets customer expectations.

2. Design and engineering evaluation: After confirming customer needs, the sheet metal processing factory will conduct design and engineering evaluation. The design team will formulate a design plan for sheet metal products based on the needs provided by the customer, and conduct an engineering assessment to determine the processing technology and required equipment.

3. Material procurement and preparation: According to the design plan, the processing plant will purchase sheet metal materials that meet the requirements and perform pre-processing processes such as cutting, bending, and stamping to prepare for subsequent processing.

4. Processing and manufacturing: After the material preparation is completed, the processing plant will process and manufacture the sheet metal products. This includes cutting, stamping, bending, welding and other processes, as well as surface treatment and assembly.

5. Quality inspection and adjustment: After processing is completed, sheet metal products will undergo strict quality inspection to ensure that the products meet customer requirements and standards. If necessary, adjustments and corrections will be made to ensure product quality.

6. Delivery and after-sales service: Finally, the processing plant delivers the completed sheet metal products to the customer and provides after-sales service. Customers can install, maintain and service the products as needed, and the processing plant will also make improvements and optimizations based on customer feedback.

In general, the sheet metal custom processing process is a systematic project from customer demand confirmation to product delivery, which requires the coordination of design, engineering evaluation, material preparation, processing and manufacturing, quality inspection and after-sales service. Through this process, processing plants can provide customers with customized sheet metal products that meet their needs and meet the needs of different industries and fields.

-

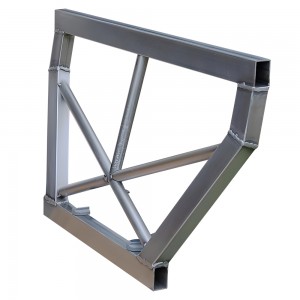

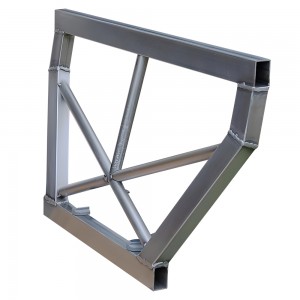

OEM Customized Metal Frame Metal Sheet Metal Processing

Customized with high-quality sheet metal materials, it has a solid structure and strong load-bearing capacity. Fine processing technology ensures that the frame has smooth lines and is aesthetically pleasing. We tailor the frame to meet different application scenarios and provide solid and reliable support for your project.

-

OEM Customized Large Animal Breeding Folding Fence

Animal breeding folding enclosure, custom processed from sheet metal, sturdy and durable, easy to fold and carry. Ingenious design, strong protection, effective isolation of external interference, to protect the safety of animals. Suitable for all kinds of breeding scenes, it is your right-hand man for animal breeding.

-

OEM Customized Metal Fencing for Farm Livestock

Large farm livestock metal fence, built with sheet metal custom craftsmanship, is sturdy and durable for superior protection. Fine welding and grinding to ensure that the fence is smooth and burr-free, to protect the safety of livestock. Adding a bright landscape to the farm, it is your ideal choice for livestock fencing.

-

OEM customized stainless steel bike rack welding fabrication

Made of high quality stainless steel material, it is sturdy and durable, anti-corrosion and anti-rust, ensuring long-lasting use. Fine sheet metal custom processing stainless steel bike rack creates a unique streamlined design that is both beautiful and practical.

-

OEM custom laser welding service metal bracket fabrication

We use high-quality stainless steel materials and fine welding to ensure that the structure of the bracket is solid, safe and reliable. Provide stable support for your products and make your customized processing better.

-

OEM Custom Heavy Duty Metal Fabricated Steel Frames

Steel frames, strong and durable with high load-bearing capacity, are ideal for your customized sheet metal products. We use high-quality steel and fine craftsmanship to ensure that each frame has excellent stability and load-bearing capacity. No matter what your needs are, we can tailor-make them to meet your customization needs.

-

OEM Custom Stainless Steel Pipe Cutting and Welding Service

We are dedicated to the customized processing of metal racks, shaping rugged and durable rack products in various forms with superior craftsmanship and precise technology. From design to molding, we strictly control every detail to ensure the stability and precision of the racks, providing solid support for your projects.

-

OEM custom bending sheet metal bracket fabrication

We specialize in the custom processing of bent sheet metal brackets, and with our rich experience and exquisite technology, we create solid and durable, beautiful and practical bracket products. We pay attention to details to ensure that each bending angle is precise and accurate, providing solid and reliable support for your projects.

-

Custom Aluminum Steel Sheet metal fabrication parts

We specialize in providing aluminum and steel sheet metal fabrication services, and with our superb skills and advanced equipment, we create high-quality and precise sheet metal fabricated parts. Each product undergoes strict quality control to ensure that it meets the needs of our customers.

-

OEM Customized Sheet Metal Processing Sheet Manufacturing

We specialize in the custom processing of large steel welded racks, using advanced welding technology to ensure a solid and accurate structure. We understand the way of sheet metal processing and build welded racks according to customer needs. With excellent quality and strong load-bearing capacity, we can provide solid support for your projects.

-

OEM customized heavy duty bracket welding processing

Heavy-duty bracket with fine welding processing and remarkable product features, solid structure, strong bearing capacity, adapting to various complex environments. Outstanding technical advantages, the use of advanced welding technology, to ensure the quality of welding, to enhance the overall performance of the product.