Sheet metal frame customization

-

OEM Customized Large Carbon Steel Cage Frame

Sheet metal custom laser cutting forming and polishing process is an advanced, efficient and precise processing technology, which has an important application value in the field of industrial manufacturing. With the continuous progress of science and technology, sheet metal customization technology will continue to develop, providing better customized solutions for various industries.

-

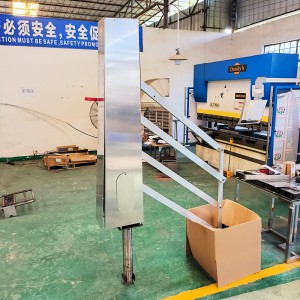

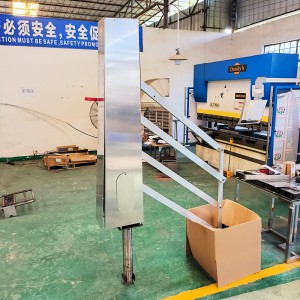

OEM customized stainless steel electrical box laser cut semi-finished products

Customized stainless steel electrical boxes are designed and manufactured according to the specific needs of customers and can be perfectly adapted to a variety of equipment, whether it is industrial machinery, communication equipment or outdoor equipment. During the customization process, we take into full consideration the size, layout and requirements of the equipment to ensure that the electrical box can perfectly accommodate the equipment and provide good maintenance space.

-

Custom Steel Safe Sheet Metal Fabrication Laser Cutting Welding

Laser cutting, bending and welding, we build steel safes with fine craftsmanship. The security is excellent and sturdy, providing all-round protection for your precious items. Whether for home or commercial applications, our safes are your smart choice. Choose us, choose quality and security.

-

Custom Metal FabricationLaser CuttingWeldingMetal Cage Forming

Sheet metal custom processing, from design to finished product, we use laser cutting and welding process to create unique products for you. With high precision, fast speed and stable quality, we make the charm of metal bloom in your products. Choose us to make every cooperation a guarantee of quality.

-

Custom Metal Framing Heavy Industry Steel Fabrication Services

We specialise in the custom processing of large stainless steel metal frames, using advanced laser technology, precise cutting and perfect welding to ensure that every detail is exquisite and perfect. With excellent quality and durability, they are widely used in various industries.

-

Specialized in custom metal stainless steel waterproof and rustproof farm fence frame

Large sheet metal frame processing customization: farm stainless steel security fence

Between the vast farmland, a strong, beautiful stainless steel fence has become the new landscape of the farm. These stunning fences come from our customized large sheet metal frame processing business. Our laser cutting and welding techniques transform every inch of steel into a work of art for the farm landscape.

The design and manufacture of these farm stainless steel fences is a perfect blend of Eastern and Western aesthetics. In terms of material selection, we insist on using high-quality stainless steel to ensure that our products can stand the test of time even in the European and American markets. And the use of laser cutting technology makes each piece of steel have precise size and perfect curvature.

The welding process is a test of the craftsman’s skill. Our technicians are rigorously trained to join two pieces of steel together in a seamless, solid, one-piece process.

Our large sheet metal frame processing business not only provides the best quality products to the European and American markets, but also adds a beautiful scenery to the farm. Choosing us is to choose the guarantee of quality and reputation. Let our products add a unique charm to your farm and become the best in the European and American market.

-

OEM customized steel and metal welded frame bracket

Customized heavy-duty sheet metal frame processing: the perfect combination of laser cutting and welding technology

Under the wave of Industry 4.0, there is a growing demand for customized heavy sheet metal frame processing. Laser cutting and welding technology, as a representative of modern manufacturing processes, has revolutionized this field.

With high precision and speed, laser cutting can process a large amount of material in a short period of time, effectively improving production efficiency. Meanwhile, the continuous advancement of welding technology, such as laser welding and friction welding, makes the connection of heavy-duty sheet metal frames stronger, greatly enhancing the stability and durability of the products.

Our team has a wealth of experience in providing one-stop services from design, production to installation according to customers’ specific needs. The combination of laser cutting and welding technology meets the demand for personalized customization while ensuring product quality and delivery time. Choosing us is choosing the double guarantee of quality and efficiency!

-

For custom industrial sheet metal welding and forming products

Industrial sheet metal frame processing customization: the application of laser cutting and welding technology

In the field of industrial manufacturing, customized processing of sheet metal frames is a key part of the process. With the development of technology, laser cutting and welding technologies have become an integral part of this process. This article will delve into the application of these two technologies in sheet metal frame processing.

Laser cutting technology: a combination of precision and efficiency

Laser cutting technology utilizes high-energy laser beams to precisely cut metal materials. Compared with traditional mechanical cutting, laser cutting has higher precision and faster speed. Its high-precision control results in smooth cut edges, reducing the need for subsequent processing. At the same time, the flexibility of laser cutting allows it to handle a wide range of complex shapes and sizes to meet a variety of customization needs.

-

For customized processing of large industrial sheet metal frames

Customization method for industrial big sheet metal frames

Sheet metal frame fabrication is a technique that is as diverse as it is vital in the world of industrial manufacturing. While sophisticated, this procedure is essential in a wide range of industrial applications, from simple structural supports to intricate mechanical enclosures. This article will go into the depths and complexity of the sheet metal framing process, looking at the design and production of custom sheet metal frames as well as their role in industrial manufacturing.

The cutting stage is the next. Modern laser or plasma cutting equipment is used to precisely cut the sheet metal into the required shape. Because of how exact the process is, tolerances are frequently expressed in millimeter fractions, guaranteeing that every component fits together flawlessly.

The bending stage then begins. To bend the sheet metal into the required shape, a press or other specialized machine is utilized. To prevent material damage and guarantee precise angles and measurements, this stage calls for expertise and precision.

Following bending, other instruments like grinders and scissors are typically used to polish or trim the edges. Taking this step is essential to getting a tidy and polished appearance.

The assembly step is the last one, during which all the separate components are put together using techniques like riveting, welding, or crimping. Paying close attention to details is essential at this point because even the smallest misalignment might cause more issues later on.

-

OEM Customized Large Outdoor Waterproof Stainless Steel Stand Enclosure

The sheet metal machined stainless steel housing is ideal for outdoor equipment. Stainless steel is corrosion-resistant and weather-resistant, able to withstand harsh weather conditions. At the same time, sheet metal processing technology can customize the shape and size of the housing to ensure perfect fit and protection of the device.

-

First Class Sheet Metal Fence Post Manufacturer

Sheet metal custom metal railings play an important role in the construction industry. Sheet metal custom railings offer many advantages over traditional railings. First of all, sheet metal custom railings can be designed and customized according to customer needs, making them perfectly blend with the architectural style. Secondly, sheet metal custom railings are made of high-quality metal materials with excellent durability and strength to ensure safety and reliability. In addition, customized railings can also add various decorative elements according to needs, such as patterns, patterns, etc., to increase the aesthetics of the building. Overall, sheet metal custom metal railings are a functional, aesthetically pleasing option that add a unique charm to a building.

-

OEM Customized Heavy Metal Stainless Steel Cutting & steel bracket

OEM Customized Heavy Metal Stainless Steel Cutting & steel bracket / Sheet Metal Fabrication Semi-finished Product Service