Customized processing uye zvakanakira isu

Zhongshan Lambert Precision Hardware Co., Ltd. ifekitori yekutengeserana kune dzimwe nyika inonyanya kugadzirisa kugadzirisa.Isu tinopa OEM, ODM uye tsika yekugadzirisa masevhisi.Zvigadzirwa zvedu ndezvemhando yepamusoro uye mutengo wemakwikwi.Vatengi vedu vakuru vanobva kumisika yepakati uye yepamusoro-soro muEurope, Australia neAmerica.

Kambani yedu yakavambwa mu2012.Isu tine vagadziri vane ruzivo uye matekiniki, uye nehunyanzvi hwekugadzira vashandi.Isu tine michina yekugadzira yepamusoro, uye yedu yekugadziridza iko kunosvika ± 0.02mm.Isu tine zvakanyanya kuomesesa zvinodiwa zvepamusoro pezvigadzirwa zvedu.Zvigadzirwa zvedu zvinorumbidzwa zvakanyanya nevatengi nekuda kwehukuru-chaiyo saizi uye yakakwana yekurapwa kwepamusoro inoita senge artworks.

Tine midziyo mikuru yekugadzira inotevera.

Laser yekucheka simbi ndiro

Iyo sheet simbi laser yekucheka muchina ndeye yakakwira chaiyo yekucheka muchina wakawanda

inoshandiswa muindasitiri yesimbi.Inoshandisa laser danda kutema simbi zvinhu uye ane

mabhenefiti ehupamhi hwepamusoro, kukurumidza kucheka, kuchinjika, kucheka kusina kubata

uye otomatiki kudzora, zvichiita kuti ive chidimbu chakakosha chemidziyo mune yazvino

indasitiri yesimbi

3D kutema pombi

Michina iyi inogona kucheka akasiyana-siyana kutenderera, sikweya, flat uye zvisina kujairika machubhu nemazvo:

- - Iron pombi

- - Galvanized pombi

- - AISI 430 chubhu

- - AISI 304 chubhu

- KUFUNGA:0.2mm - 50mm

- MAX SIZE:φ220mm*6000mm

- KUSHINGIRIRA:± 0.05mm

Sheet simbi yekubhenda michina

Sheet simbi yekubhenda muchina imhando yemuchina nemidziyo zvakanyanya

yakagadzirirwa kugadzirisa sheet metal zvinhu.Sheet simbi yekubhenda muchina

ine zvakanakira kushanda kwepamusoro, kunyatsojeka, kuchinjika, kuponesa munhu

zviwanikwa uye kuvandudza kunaka kwechigadzirwa.Iine huwandu hwakawanda hwekushandisa

uye inogona kusangana nezvinodiwa zvemaindasitiri akasiyana uye minda yepepa simbi kugadzirisa

Robhoti welding

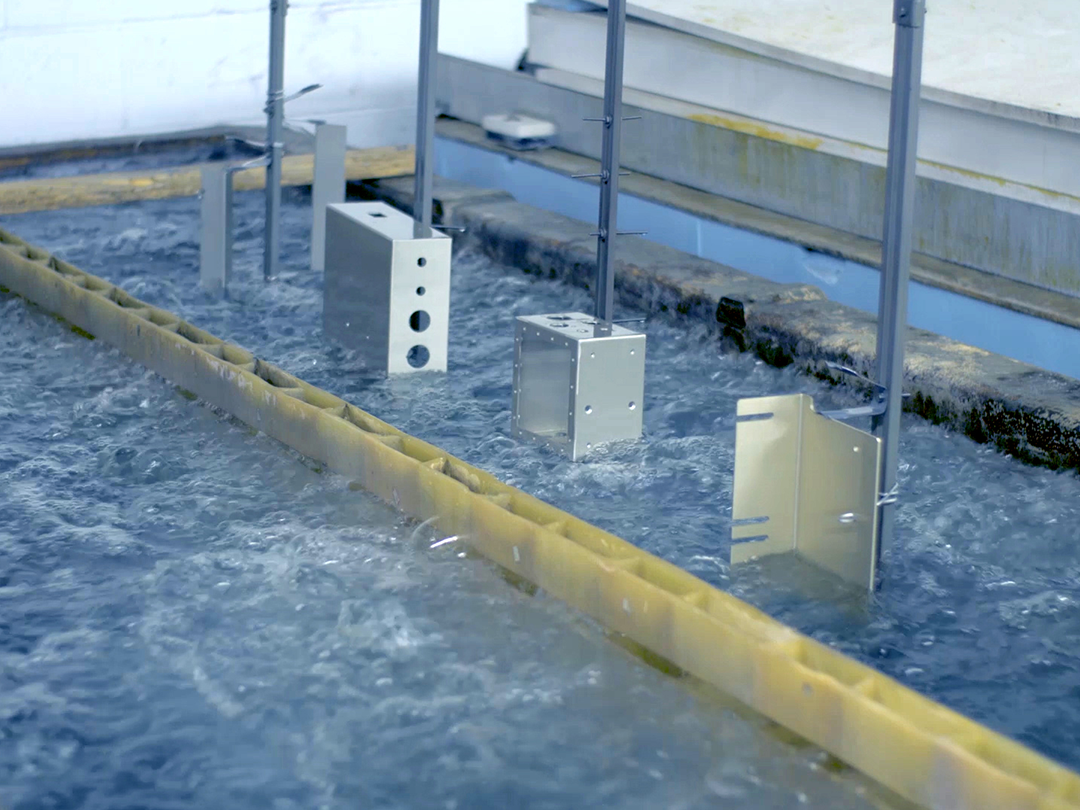

Robhoti TIG(Tungsten Inert Gasi) welding centre.Robhoti MIG(Metal-arc Inert Gas) welding centre.Yakasanganiswa neakasiyana akakosha magadzirirwo, isu tinogona kugadzirisa akasiyana siyana akaomarara.Tinogona kushandisa otomatiki welding tekinoroji mukati mebhokisi

Laser yekucheka michina yepepa resimbi

Nekumhanya kwakanyanya, kurongeka kwakanyanya, kuchinjika kwakanyanya, kuderera burr uyeyakakwirira kubereka, sheet simbi laser yekucheka michina yakawandainoshandiswa mushizha simbi yekugadzirisa munda kuvandudza kugadzirisakunyatsoshanda uye kunaka kwechigadzirwa

Laser tube cutter

Iyo sheet simbi laser chubhu yekucheka inoshanda uye chaiyo muchina wakagadzirirwakucheka machubhu esimbi.Iyo inoratidzira kumhanya kwekucheka, yakanyanya kurongeka uye kuchinjika,kugonesa kukurumidza kupera kwebasa rekucheka uye kuvimbisa kunaka uyekurongeka kwenzvimbo yakachekwa

3D dhizaini dhizaini

Ne 3D dhizaini yedhizaini, vagadziri vanogona kutarisa kukodzera uye kugadzirwa kwezvigadzirwa zvavo kumberi, kugadzirisa dhizaini mhinduro, kuderedza mutengo wekugadzira uye kuve nechokwadi chemhando uye nemazvo echigadzirwa chekupedzisira.

Tinokwanisa kupa zvakasiyana-siyana zvemhando yepamusoro kurapwa.Semuenzaniso: kukuya, kupukuta, kudhirowa waya, electroplating, kupfapfaidza hupfu, anodizing, nezvimwe.

Sheet metal welding inzira umo maviri kana anopfuura mapepa esimbi ekushanda anobatanidzwa nekupisa kana kumanikidza.Inoshandiswa kubatanidza mapepa akaonda esimbi uye inowanzoshandiswa mukugadzira simbi zvivako, zvikamu uye midziyo nezvimwewo. Nzira dzakasiyana-siyana dzinogona kushandiswa pakugadzira simbi yesimbi, kusanganisira stud welding, fillet welding, spot welding uye laser welding.

Polishing: Kukuya nekukwenenzverwa kwepepa resimbi pachishandiswa maturusi anokwenya uye mabrasives kuita kuti pamusoro pave kutsvedzerera, kupfava uye kupenya.

Sandblasting: A high pressure sandblaster inoshandiswa kuputika jecha pashizha resimbi kuti ibvise oxidation yepasi, mavara uye maburrs kuburikidza neabrasion uye kukanganisa, zvichiita kuti pamusoro pave kutsvedzerera uye yunifomu.

Kupfapfaidza: Uchishandisa pfuti yekupfapfaidza, pendi inoiswa pamusoro pemashizha esimbi zvigadzirwa zvekudzivirira nekunakisa.Kupfapfaidza kunogona kuitwa nemhando dzakasiyana dzependi senge lacquer, poda coating etc.

Chitarisiko, corrosion resistance uye michina yemashizha simbi inogona kuvandudzwa neanodising.Anodising kazhinji inosanganisira matanho ekuita senge pickling uye kuchenesa, electrolytic oxidation uye kuisa chisimbiso kurapwa.

Sheet simbi plating yakajairika pamusoro pekurapa maitiro kuti uwedzere corrosion kuramba, aesthetics uye magetsi conductivity yepepa simbi nekuiputira nesimbi yakatetepa kana alloy.

Isu tiri nyanzvi yefekitori yetsika, iyo inogona kusangana nezvinodiwa zvehukuru hwakasiyana, zvinhu uye kurapwa kwepamusoro.Isu takazvipira kugadzira win-win mamiriro.Kana uine mapurojekiti kana mazano, ndapota inzwa wakasununguka kutibata nesu.Unogona kuvimba nesu kugadzira zvigadzirwa.Chikwata chako chinogona kutarisa pakushambadzira uye kuwana hunyanzvi hwepamusoro.