Tsika Stainless Simbi Metal Zvikamu welding Service

Product Description

Resistance welding

Resistance welding inzira yekugadzira iyo iyo workpiece inosanganiswa uye kumanikidzwa kunoshandiswa kuburikidza ne electrode, uye magetsi emagetsi anoshandiswa kuburikidza nekudzivirira kupisa kunogadzirwa nepamusoro pekubatana uye nzvimbo yakatarisana yejoini.Resistance welding inzira yekupisa iyo workpiece kune yakanyungudutswa kana yepurasitiki mamiriro nemagetsi emagetsi anoyerera nepakati pekubatana uye nzvimbo dziri pedyo.Pane nzira ina huru dzekudzivirira welding, dzinoti spot welding, seam welding, projection welding uye butt welding.

Carbon dioxide welding

Iyo inodzivirira gasi yecarbon dioxide arc welding icarbon dioxide (dzimwe nguva musanganiswa we CO2 + Ar).Inonyanya kushandiswa kune manual welding.Nekuda kwesimba rakakosha rekupisa kwemuviri wecarbon dioxide gasi, kana uchishandisa yakajairwa welding magetsi, hazvibviri kuumba yakaenzana axial yemahara shanduko nekunyungudutsa simbi pakupera kwewaya welding, izvo zvinowanzoda pfupi dunhu uye droplet mitsipa. kuputika.Naizvozvo, zvichienzaniswa neMIG welding yemahara shanduko, kune yakawanda splash.Asi kana kushandiswa kwemhando yepamusoro welding machine, sarudzo yakarurama yeparameters, inogona kuwana yakanyatsogadzikana welding process, kuitira kuti spatter ideredze kusvika padhigirii shoma.Nekuda kwemutengo wakaderera wegasi rinodzivirira rinoshandiswa, iyo weld inoumbwa zvakanaka kana uchishandisa pfupi dunhu shanduko, yakabatana nekushandiswa kwewaya ine deoxidizer inogona kuwanikwa pasina kukanganisa kwemukati kwehutano welding joint.Naizvozvo, iyi nzira yewelding yave imwe yedzakanyanya kukosha nzira dzekugadzira ferrous simbi zvinhu.

Argon arc welding

Argon arc welding i tekinoroji yekukwenenzvera inoshandisa argon gasi segasi rinodzivirira.Iyo inozivikanwawo se argon body protection welding.Iko kupfuudza argon inodzivirira gasi yakatenderedza arc welding kuti iparadzanise mhepo kunze kwenzvimbo yewelding uye kudzivirira oxidation yenzvimbo yewelding.

Argon arc welding tekinoroji iri pahwaro hweiyo yakajairwa magetsi arc welding, uchishandisa iyo argon gasi chengetedzo yesimbi welding zvinhu, kuburikidza nepamusoro ikozvino pane welding inotsigira weld zvinhu zvinonyunguduka kuita yemvura pool kuumbwa, kukonzera iyo weld simbi uye weld zvinhu. metallurgy yakasanganiswa nemhando yewelding tekinoroji, mukupisa kwakanyanya kunyunguduka welding pane argon nguva dzose, ita kuti weld material irege kusangana neokisijeni mumhepo, Saka kudzivirira oxidation yewelding zvinhu, saka unogona weld Stainless simbi, iron simbi.

Laser welding

Laser welding inogona kuwanikwa nekuenderera kana pulsed laser beam.Nheyo yelaser welding inogona kukamurwa kuita kupisa conduction welding uye laser yakadzika fusion welding.Kana simba remagetsi riri pasi pe10-10 W/cm, kupisa conduction welding, uye kudzika kwewelding uye kumhanya kwewelding kunononoka.Kana simba resimba rakakura kupfuura 10 ~ 10 W/cm, simbi yesimbi inonyungudika kuita "makomba" pasi pechiito chekupisa, ichigadzira yakadzika fusion welding, iyo ine maitiro ekukurumidza welding kumhanya uye chiyero chikuru chekudzika kusvika pahupamhi.

Nheyo yekupisa conduction laser welding ndeye: iyo laser mwaranzi inopisa pamusoro kuti igadziriswe, uye kupisa kwepasi kunopararira mukati kuburikidza nekupisa conduction.Nekudzora ma laser parameter akadai sehupamhi, simba, simba repamusoro uye kudzokorora frequency ye laser pulse, workpiece inonyungudutswa uye dziva rakanyungudutswa rinoumbwa.

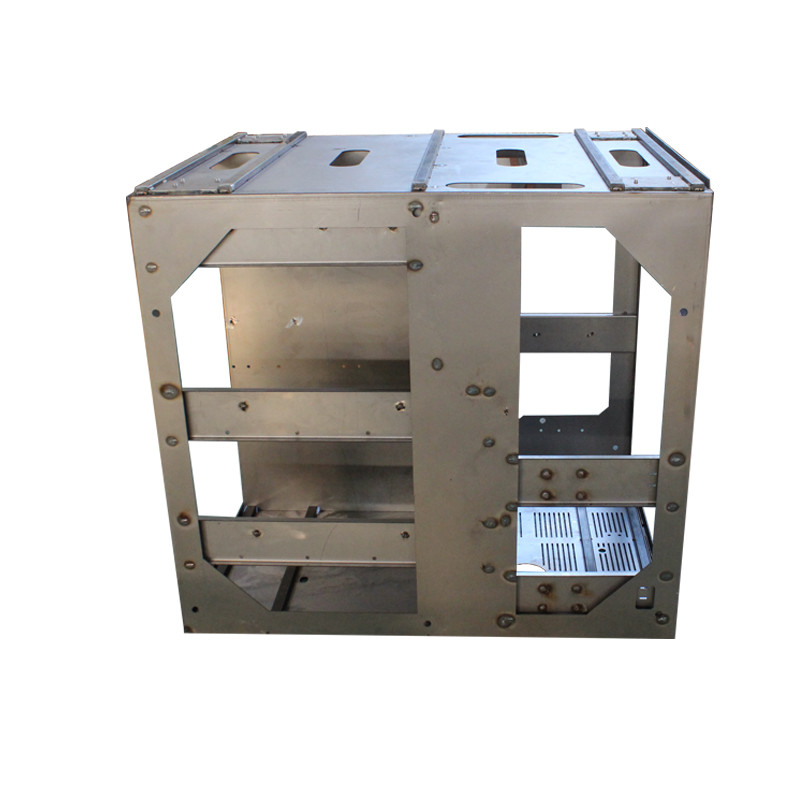

Lambert sheet simbi tsika yekugadzirisa mhinduro mupi.

Tine makore gumi eruzivo rwekutengeserana kune dzimwe nyika, isu tiri nyanzvi mune yakakwirira precision sheet simbi kugadzirisa zvikamu, laser kucheka, sheet simbi kupeta, simbi mabhureki, sheet simbi chassis shells, chassis magetsi ekupa housings, etc. , polishing, sandblasting, spraying, plating, iyo inogona kushandiswa kune zvigadzirwa zvekutengeserana, zviteshi, mabhiriji, zvivakwa, zvivakwa, mahotera, akasiyana-siyana epombi masisitimu, etc. emhando uye inoshanda masevhisi ekugadzirisa kune vatengi vedu.Isu tinokwanisa kugadzira sheet simbi zvikamu zveakasiyana maumbirwo kuti asangane nevatengi vedu 'kwakazara machining zvinodiwa.Isu tiri kugara tichigadzira uye kugadzirisa maitiro edu kuti tive nechokwadi chemhando uye kuendesa, uye isu tinogara "takatarisana nevatengi" kupa vatengi vedu sevhisi yemhando yepamusoro uye kuvabatsira kubudirira.Tinotarisira kuvaka hukama hwenguva refu nevatengi vedu munzvimbo dzese!