Laser Welding Services

-

sheet metal enclosure fabrication service solutions for a wide range of industries.

Custom sheet metal enclosure processing is an important manufacturing process that provides protection and aesthetic appearance to a variety of equipment and machinery. Stainless steel, as the main raw material, is widely used in the manufacture of sheet metal casings and is favored for its corrosion resistance, high strength, and easy cleaning. In order to further enhance the anti-rust performance of the stainless steel shell, surface treatment such as anodizing, galvanizing or spraying a protective layer can be achieved. At the same time, precision machining technology is crucial for the manufacturing of customized sheet metal casings to ensure accurate dimensions and stable quality. Whether it is electronic equipment, medical equipment or mechanical equipment, customized sheet metal casings can be individually designed and manufactured according to customer needs to meet the requirements of different industries and uses. Therefore, custom sheet metal housing processing, as a core manufacturing technology, not only plays an important role in the industrial field, but will also continue to be of great significance in future development.

-

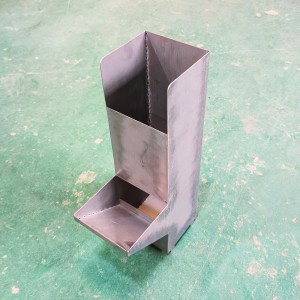

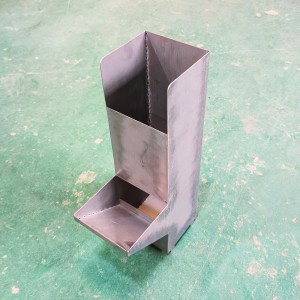

Custom sheet metal enclosure stainless steel electrical box

Stainless steel electrical boxes, rugged and durable, offer custom sheet metal fabrication services for your equipment. Adopting unique anti-rust treatment to ensure that the electrical box is as good as new for a long time. Good heat dissipation performance, to protect the stable operation of equipment.

-

OEM custom metal casing laser bending and welding service

With our custom sheet metal fabrication, we specialise in shaping unique metal enclosures for you. Individualised design, precise craftsmanship, carving every detail to ensure superior quality. Trust us to give your brand an extraordinary metal charm and create a brilliant future together!

-

Custom stainless steel electrical box sheet metal processing

Focusing on the sheet metal custom processing industry, we provide you with superior stainless steel electrical box solutions. Our service is not only reflected in the high-quality material selection and superb craftsmanship, but also lies in the whole process of worry-free personalised customised service.

-

OEM custom sheet metal steel electrical box manufacturing

We provide professional and high quality customised steel electrical box service for your project! Using high quality materials to ensure that each steel electrical box is precisely calculated and made.

With unique design and fine craftsmanship, your steel electrical box will not only be safe and durable, but also become the highlight of the space. -

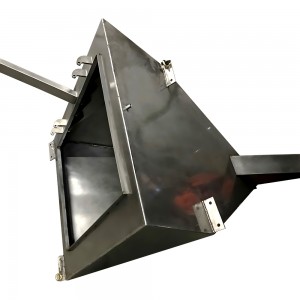

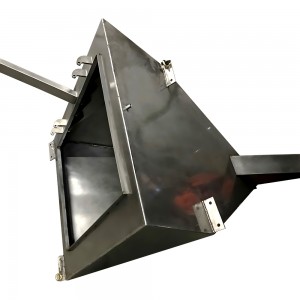

OEM custom sheet metal enclosure case laser fabrication

Stainless steel sheet metal enclosures combine industrial aesthetics with durability to provide rugged protection for your equipment. We select the finest stainless steel materials and use advanced sheet metal technology to customise whatever size or design you require.

-

What is Sheet Metal Fabrication Engineering

What is Sheet Metal Fabrication Engineering

Sheet metal processing engineering refers to a comprehensive cold working process for thin metal sheets (usually under 6mm), including shearing, stamping, bending, welding, riveting, splicing, molding and other processes to produce the desired shape and size. This type of processing is widely used in manufacturing industries such as automotive, aviation, electronics and electrical appliances. The distinctive feature of sheet metal processing is that the thickness of the same part is consistent and remains unchanged during processing. Its processing generally includes steps such as shearing, bending, stamping, welding, etc., and requires certain geometric knowledge.Sheet metal processing equipment mainly includes metal presses, shears and punches and other general-purpose machinery and equipment, the molds used are some simple and universal tooling molds and special molds for special workpieces with special molding. It is characterized by concentrated processes, high degree of mechanization and easy to realize automated production. In the process of sheet metal processing, attention needs to be paid to material selection, process design, quality control and other aspects.

In conclusion, sheet metal processing engineering is a kind of processing technology for thin metal plates, which is characterized by high precision, light weight, diversification and high efficiency, and can meet the needs of different fields.

-

Custom Sheet Metal Welding Component Metal Fabrication

We specialise in custom sheet metal and even more so in metal welding. With state-of-the-art processes and equipment, we ensure that every weld is tightly fitted, strong and aesthetically pleasing. Whether it’s a prototype or a mass-produced product, we have the high-quality welding technology to meet your needs.

-

For precision stainless steel laser cutting steel welding bending service

Outdoor equipment needs to withstand harsh environments, and our custom stainless steel outdoor waterproof and rustproof sheet metal enclosures are just the thing for you. High-quality stainless steel material, through precision sheet metal processing, to create a strong and durable shell, to provide strong protection for your equipment. Rain or shine, there is no place for moisture to penetrate, and the internal components are perfectly protected. Choose our enclosure to make your equipment durable and long-lasting in any environment for your safety. Let your equipment can operate stably even in harsh environments, and help your business.

-

Custom sheet metal working parts stainless steel fabrication

Laser cut and welded stainless steel with excellent quality and high precision. Advanced technology is used to ensure that every detail is perfect. We can provide you with the best quality service, choose us, you will get the most reliable sheet metal custom processing solutions for your business.

-

Custom Stainless Steel Enclosure Metal Fabrication Laser Cutting

Laser cut and welded stainless steel, we utilise advanced laser technology to cut and weld stainless steel materials to perfect precision, ensuring that every detail meets high standards. No matter what kind of customised sheet metal products you need, we can respond quickly and provide excellent processing services.

-

OEM custom large stainless steel sheet metal fabrication products

We create an unrivalled sheet metal customisation experience for you! We specialise in custom fabrication of stainless steel products. High precision, superior quality and long-lasting durability. From precision parts to industrial equipment, we meet your various needs with our expertise.