Laser Welding Services

-

Customized eco-friendly 304/316 stainless steel pet dog/pet cat food bowl

The sheet metal processed stainless steel pet bowl not only looks stylish, but is also environmentally friendly and sustainable. Stainless steel material does not produce harmful substances and can be reused. Sheet metal processing technology is precise, reducing waste and carbon emissions. Choosing this kind of pet bowl not only meets the needs of pets, but also pays attention to environmental protection.

-

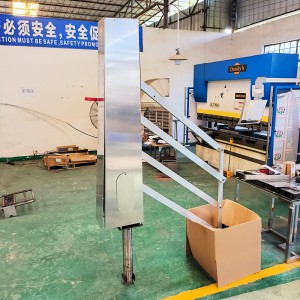

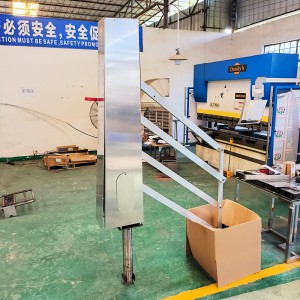

OEM Customized Large Outdoor Waterproof Stainless Steel Stand Enclosure

The sheet metal machined stainless steel housing is ideal for outdoor equipment. Stainless steel is corrosion-resistant and weather-resistant, able to withstand harsh weather conditions. At the same time, sheet metal processing technology can customize the shape and size of the housing to ensure perfect fit and protection of the device.

-

Sheet metal processing galvanized sheet metal animal feeding troughs

Sheet metal processing is a common method of metal processing, which involves cutting, bending, welding, and painting metal sheets into the required shape and size. As a corrosion-resistant metal sheet, galvanized sheet is widely used in sheet metal processing. An animal feeding trough is a container used for animals to eat. Its quality and design are very important for animal food hygiene and safety. Sheet metal processing galvanized sheet animal feeding troughs have many advantages. First of all, galvanized sheets have good corrosion resistance and can be used in humid environments for a long time without rusting easily. This is important for animal feeding troughs as they are often exposed to liquids and substances such as water, food and animal waste. Secondly, the surface of galvanized sheet is flat, smooth and easy to clean. Animal feeding troughs need to be cleaned frequently to ensure food hygiene and animal health. The smooth surface of galvanized sheets makes cleaning easier and faster, while also reducing the growth of bacteria and dirt. In addition, galvanized sheets have high strength and can withstand the extrusion and collision of animals when eating. Animals usually chew hard on the feeding trough when eating. High-strength galvanized plates can effectively prevent the feeding trough from being broken or damaged in the middle, ensuring that animals can eat smoothly. In short, the sheet metal processed galvanized plate animal feeding trough is a high-quality choice. It is not only corrosion-resistant, easy to clean and high in strength, but can also effectively ensure the hygiene and safety of animal food. Whether it is livestock on the farm or experimental animals in the laboratory, this feeding trough can meet their needs and provide a healthy and safe eating environment.

-

Custom Aluminum Stainless Steel Sheet Metal Enclosure Electrical Box

Sheet metal machined stainless steel housings provide superior corrosion resistance and strength for use in multiple industries. Its precise manufacturing process ensures that the case fits perfectly and provides reliable protection and beautiful appearance. Stainless steel material is also high temperature resistant and easy to clean, making it suitable for use in harsh environments. Whether it is electronic equipment, home appliances or the automotive industry, stainless steel housings processed from sheet metal are the ideal choice.

-

Sheet metal customized farm animal feeding trough

Sheet metal fabricated farm animal troughs provide a quality feed storage solution for farmers. Carefully designed and manufactured, the troughs are able to hold large quantities of feed and ensure that it is dry and fresh. At the same time, the robustness of the sheet metal material ensures the durability and long life of the troughs. This technology makes farm management more efficient and helps farmers take better care of their animals.

-

OEM customized precision stainless steel sheet metal fabrication

We provide precision sheet metal stainless steel cutting parts with reliable quality. Through advanced technology and equipment, we ensure that customer requirements and specifications are met.

-

OEM customized large structural stainless steel/bracket laser cutting sheet metal fabrication

Sheet metal laser cutting technology plays an important role in the production of stainless steel formed housings. Its high precision, high efficiency, no need for contact and adaptability to complex shapes make sheet metal laser cutting an ideal choice for the production of high-quality stainless steel molding shells. With the continuous progress of technology and the promotion of application, it is believed that sheet metal laser cutting technology will play an increasingly important role in the metal processing industry.

-

china manufacture custom processing metal sheet parts

Let’s learn about laser cutting and molding technology. Laser cutting is a process that utilizes a high-energy laser beam to cut sheet metal materials into specific shapes. By controlling the focus and intensity of the laser beam, precise and fast cutting can be realized. Compared with traditional mechanical cutting methods, laser cutting has the following advantages:

High precision: Laser cutting can achieve more precise shapes and sizes, whether it is a simple straight line or a complex curve.

Fast: Laser cutting is fast, which can greatly improve the production efficiency, especially suitable for mass production.

Flexibility: Laser cutting can handle a wide variety of materials, including steel, aluminum, stainless steel, and more. It can also cut sheet metal materials of various thicknesses, enabling the customization of a wide range of products.

-

First Class Sheet Metal Fence Post Manufacturer

Sheet metal custom metal railings play an important role in the construction industry. Sheet metal custom railings offer many advantages over traditional railings. First of all, sheet metal custom railings can be designed and customized according to customer needs, making them perfectly blend with the architectural style. Secondly, sheet metal custom railings are made of high-quality metal materials with excellent durability and strength to ensure safety and reliability. In addition, customized railings can also add various decorative elements according to needs, such as patterns, patterns, etc., to increase the aesthetics of the building. Overall, sheet metal custom metal railings are a functional, aesthetically pleasing option that add a unique charm to a building.

-

OEM Customized Heavy Metal Stainless Steel Cutting & steel bracket

OEM Customized Heavy Metal Stainless Steel Cutting & steel bracket / Sheet Metal Fabrication Semi-finished Product Service

-

OEM Customized Stainless Steel Safe Metal Cabinet semi-finished

A customized safe with sheet metal processing is a manufactured security storage device used to protect valuables and documents.

-

OEM custom metal fabrication stainless steel foldable molded products

Customized stainless steel cart is a common logistics and transportation equipment, widely used in factories, warehouses, supermarkets and other places. It is made of stainless steel material with corrosion resistance, abrasion resistance and sturdy structure, which can meet the material handling needs in various environments