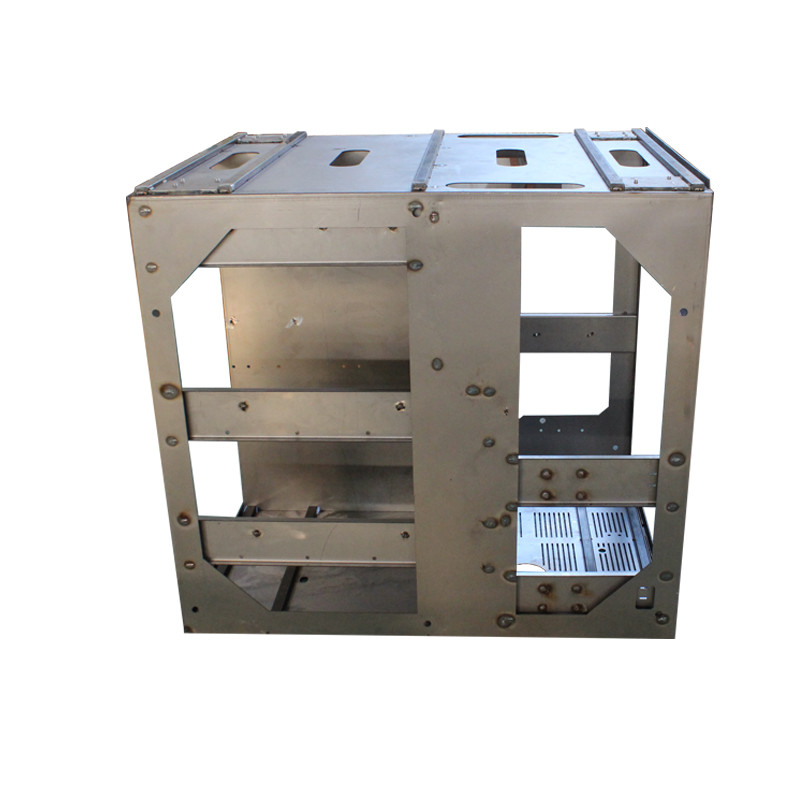

Isevisi yokushisela Izingxenye Zensimbi Engagqwali Ngokwezifiso

Incazelo Yomkhiqizo

Ukumelana nokushisela

I-Resistance welding iyindlela ye-welding lapho i-workpiece ihlanganiswa khona futhi ingcindezi isetshenziswa nge-electrode, futhi amandla kagesi asetshenziswa ngokushisa kokumelana okukhiqizwa indawo yokuxhumana nendawo eseduze yokuhlangana.I-Resistance welding iyindlela yokushisa i-workpiece esimweni esincibilikisiwe noma sepulasitiki ngamandla kagesi ageleza endaweni yokuxhumana nasezindaweni eziseduze.Kunezindlela ezine eziyinhloko zokushisela ukumelana, okuyi-spot welding, i-seam welding, i-projection welding kanye ne-butt welding.

I-Carbon dioxide Welding

Igesi evikelayo ye-carbon dioxide arc welding yi-carbon dioxide (kwesinye isikhathi ingxube ye-CO2+Ar).Ikakhulu isetshenziselwa i-welding manual.Ngenxa yethonya elikhethekile lezinto ezibonakalayo ezishisayo zegesi ye-carbon dioxide, lapho kusetshenziswa amandla okushisela okujwayelekile, akunakwenzeka ukwakha inguquko yamahhala ye-axial ngokuncibilikisa insimbi ekugcineni kocingo lwe-welding, okuvame ukudinga ukujikeleza okufushane kanye ne-droplet necking. ukuqhuma.Ngakho-ke, uma kuqhathaniswa nenguquko yamahhala ye-MIG yokushisela, kukhona i-splash eyengeziwe.Kodwa uma ukusetshenziswa komshini we-welding wekhwalithi ephezulu, ukukhetha okulungile kwemingcele, kungathola inqubo ye-welding ezinzile kakhulu, ukuze i-spatter iyancipha ibe yizinga elincane.Ngenxa yezindleko eziphansi zegesi elivikelayo elisetshenzisiwe, i-weld yakheka kahle uma usebenzisa inguquko yesifunda esifushane, okuhambisana nokusetshenziswa kocingo oluqukethe i-deoxidizer ingatholakala ngaphandle kokukhubazeka kwangaphakathi kwekhwalithi ye-welding joint.Ngakho-ke, le ndlela yokushisela isiphenduke enye yezindlela zokushisela ezibaluleke kakhulu zensimbi eyinsimbi.

I-Argon arc welding

I-Argon arc welding ubuchwepheshe bokushisela obusebenzisa i-argon gas njengegesi evikelayo.Kwaziwa nangokuthi i-argon body protection welding.Kuwukudlula igesi elivikelayo le-argon elizungeze i-arc welding ukuze kuhlukaniswe umoya ngaphandle kwendawo yokushisela futhi kuvimbele i-oxidation yendawo yokushisela.

I-Argon arc welding technology isesisekelo sesimiso sokushisela kwe-arc kagesi evamile, kusetshenziswa ukuvikelwa kwegesi ye-argon yezinto zokushisela zensimbi, ngokusebenzisa umthamo ophezulu we-welding weld weld material ukuncibilika kube ukwakheka kwechibi le-liquid, kubangele insimbi ye-weld kanye nezinto zokushisela. i-metallurgy ehlangene nohlobo lobuchwepheshe bokushisela, ekushiseni okuphezulu okuncibilika kwe-welding ku-argon njalo, yenza i-weld material ayikwazi ukuthintana nomoya-mpilo emoyeni, ngaleyo ndlela ivimbele i-oxidation yezinto zokushisela, ukuze ukwazi ukushisela insimbi engagqwali, insimbi yensimbi.

I-laser welding

Ukushiswa kwe-laser kungenziwa ngokuqhubekayo noma nge-pulsed laser beam.Umgomo we-laser welding ungahlukaniswa ube yi-welding conduction welding kanye ne-laser deep fusion welding.Uma ukuminyana kwamandla kungaphansi kuka-10-10 W/cm, kuwukushisela ukushisa, futhi ukujula kwe-welding nesivinini sokushisela kuhamba kancane.Lapho ukuminyana kwamandla kungaphezu kuka-10 ~ 10 W/cm, indawo yensimbi igoqeka ibe "izimbobo" ngaphansi kwesenzo sokushisa, yakha i-fusion welding ejulile, enezici zejubane lokushisela okusheshayo kanye nesilinganiso esikhulu sokujula kuya kobubanzi.

Isimiso sokushiswa kwe-laser conduction siwukuthi: imisebe ye-laser ishisa ingaphezulu ukuze icutshungulwe, futhi ukushisa okungaphezulu kusakazeka ngaphakathi ngokuqhutshwa kokushisa.Ngokulawula imingcele ye-laser njengobubanzi, amandla, amandla aphezulu kanye nemvamisa yokuphindaphinda kwe-laser pulse, ucezu lokusebenza luyancibilika bese kwakhiwa ichibi elithile elincibilikisiwe.

I-Lambert sheet metal custom processing solutions provider.

Sinesipiliyoni seminyaka eyishumi ekuhwebeni kwamanye amazwe, sisebenza ngokukhethekile ezingxenyeni zokucubungula insimbi zeshidi elinembayo, ukusika i-laser, ukugoba kwensimbi yeshidi, abakaki bensimbi, amagobolondo e-chassis ensimbi, izindlu zokuphakelwa kwamandla ka-chassis, njll. , ukupholishwa, ukuqhunyiswa kwesihlabathi, ukufutha, ukucwenga, okungase kusetshenziswe emiklamweni yezentengiselwano, amachweba, amabhuloho, ingqalasizinda, izakhiwo, amahhotela, izinhlelo ezihlukahlukene zamapayipi, njll. ikhwalithi kanye nezinsiza ezisebenzayo zokucubungula kumakhasimende ethu.Siyakwazi ukukhiqiza izingxenye zeshidi lensimbi yokwakheka okuhlukahlukene ukuze sihlangabezane nezidingo eziphelele zemishini yamakhasimende ethu.Sihlala sisungula izinto ezintsha futhi sithuthukisa izinqubo zethu ukuze siqinisekise ikhwalithi nokulethwa, futhi sihlale “sigxile kumakhasimende” ukuze sinikeze amakhasimende ethu isevisi yekhwalithi futhi siwasize afinyelele impumelelo.Sibheke ngabomvu ukwakha ubudlelwano besikhathi eside namakhasimende ethu kuzo zonke izindawo!