Ukwenza ngokwezifiso uhlaka lwensimbi yeshidi

-

Ukuze uthole inkambiso yezimboni sheet metal welding kanye nemikhiqizo ukwakha

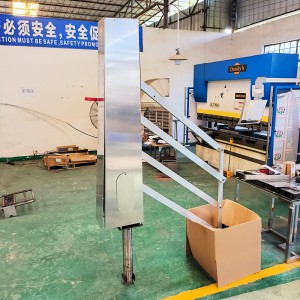

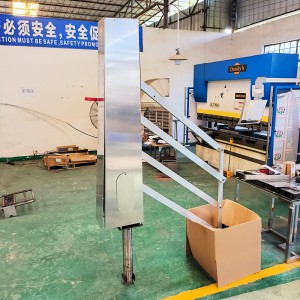

I-Industrial sheet metal frame processing customization: ukusetshenziswa kwe-laser cutting and welding technology

Emkhakheni wokukhiqiza izimboni, ukucutshungulwa okwenziwe ngokwezifiso kwamafreyimu ensimbi kuyingxenye ebalulekile yenqubo.Ngokuthuthuka kobuchwepheshe, ubuchwepheshe be-laser cutting kanye ne-welding sebuyingxenye ebalulekile yale nqubo.Lesi sihloko sizocubungula ukusetshenziswa kwalezi zindlela ezimbili zobuchwepheshe ekucubunguleni uhlaka lwensimbi yeshidi.

Ubuchwepheshe bokusika i-Laser: inhlanganisela yokunemba nokusebenza kahle

Ubuchwepheshe bokusika i-laser busebenzisa imishayo ye-laser enamandla kakhulu ukusika izinto zensimbi ngokunembile.Uma kuqhathaniswa nokusika kwemishini yendabuko, ukusika kwe-laser kunokunemba okuphezulu kanye nesivinini esisheshayo.Ukulawula kwayo okunembayo okuphezulu kubangela imiphetho yokusika ebushelelezi, kunciphisa isidingo sokucutshungulwa okulandelayo.Ngasikhathi sinye, ukuguquguquka kokusika kwe-laser kuvumela ukuthi iphathe ububanzi obuhlukahlukene bobunjwa obuyinkimbinkimbi namasayizi ukuze kuhlangatshezwane nezidingo ezahlukahlukene zokwenza ngokwezifiso.

-

Ngokucubungula okwenziwe ngokwezifiso kwamafreyimu amakhulu ensimbi yeshidi lezimboni

Indlela yokwenza ngokwezifiso amafreyimu ensimbi yeshidi elikhulu lezimboni

Ukwenziwa kohlaka lwensimbi yeshidi kuyindlela ehluke kakhulu njengoba ibalulekile emhlabeni wokukhiqiza izimboni.Nakuba iyinkimbinkimbi, le nqubo ibalulekile ezinhlobonhlobo zezinhlelo zokusebenza zezimboni, kusukela ezisekelweni ezilula zesakhiwo kuya ezindaweni ezivalekile zemishini.Lesi sihloko sizongena ekujuleni nokuba yinkimbinkimbi kwenqubo yokufaka uhlaka lwensimbi yeshidi, sibheke ukuklanywa nokukhiqizwa kwamafreyimu ensimbi eshidi langokwezifiso kanye nendima yawo ekukhiqizeni izimboni.

Isiteji sokusika silandelayo.Imishini yesimanje yokusika i-laser noma i-plasma isetshenziselwa ukusika kahle insimbi yeshidi ibe yisimo esidingekayo.Ngenxa yokuthi le nqubo inembe kangakanani, ukubekezelelana kuvame ukuvezwa ngamafrakshini amamilimitha, okuqinisekisa ukuthi zonke izingxenye zihlangana ndawonye ngokungenasici.

Isiteji sokugoba bese siqala.Ukugoba insimbi yeshidi ibe yisimo esidingekayo, kusetshenziswa umshini wokunyathelisa noma omunye umshini okhethekile.Ukuze uvimbele ukulimala kwezinto kanye nokuqinisekisa ama-engeli anembile nezilinganiso, lesi sigaba sidinga ubuchwepheshe nokunemba.

Ngemva kokugoba, ezinye izinsimbi ezifana nezigayo nezikelo ngokuvamile zisetshenziselwa ukupholisha noma ukunquma imiphetho.Ukuthatha lesi sinyathelo kubalulekile ukuze uthole ukubukeka okuhlanzekile nokupholile.

Isinyathelo somhlangano ngesokugcina, lapho zonke izingxenye ezihlukene zihlanganiswa kusetshenziswa amasu afana ne-riveting, welding, noma crimping.Ukunaka imininingwane kubalulekile okwamanje ngoba nokungaqondani kahle okuncane kungabangela izinkinga eziningi kamuva.

-

I-OEM Eyenziwe Ngokwezifiso Indawo Enkulu Yangaphandle Engangeni Manzi Yensimbi Engagqwali

Izindlu zensimbi engagqwali ezenziwe ngomshini weshidi zilungele imishini yangaphandle.Insimbi engagqwali iyamelana nokugqwala futhi imelana nesimo sezulu, ikwazi ukumelana nezimo zezulu ezinzima.Ngesikhathi esifanayo, ubuchwepheshe bokucubungula insimbi yeshidi bungenza ngokwezifiso ukuma nobukhulu bezindlu ukuze kuqinisekiswe ukulingana okuphelele nokuvikelwa kwedivayisi.

-

Ikilasi Lokuqala Leshidi Lensimbi Yocingo Lomkhiqizi Weposi

Izinsimbi zensimbi ezenziwe ngokwezifiso zeshidi zidlala indima ebalulekile embonini yezokwakha.Izinsimbi zokwenza ngokwezifiso zeshidi zinikeza izinzuzo eziningi kunojantshi bendabuko.Okokuqala, izinsimbi zokwenza ngokwezifiso zeshidi zingaklanywa futhi zenziwe ngezifiso ngokuya ngezidingo zamakhasimende, zizenze zihlangane ngokuphelele nesitayela sezakhiwo.Okwesibili, izinsimbi zensimbi ezenziwe ngokwezifiso zenziwe ngezinto zensimbi ezisezingeni eliphezulu ezinokuqina okuhle kakhulu namandla okuqinisekisa ukuphepha nokuthembeka.Ngaphezu kwalokho, izitimela ezenziwe ngokwezifiso zingaphinda zengeze izakhi ezihlukahlukene zokuhlobisa ngokuvumelana nezidingo, njengamaphethini, amaphethini, njll, ukwandisa ubuhle besakhiwo.Sekukonke, izinsimbi zensimbi ngokwezifiso zeshidi ziyinketho esebenzayo, ejabulisa ngobuhle eyengeza ukukhanga okuyingqayizivele esakhiweni.

-

I-OEM Yenziwe Ngokwezifiso Insimbi Esindayo Yensimbi Engagqwali & ubakaki wensimbi

I-OEM Eyenziwe Ngezifiso Yensimbi Esindayo Esindwayo & ubakaki wensimbi / Isevisi Yomkhiqizo Eqediwe Kancane Yeshidi Lokwenziwa Kwensimbi

-

Imikhiqizo ebunjiwe yensimbi engagqwali ye-OEM eyenziwe ngokwezifiso

Ikalishi elenziwe ngokwezifiso lensimbi engagqwali iyinto evamile yezinto zokuhamba nezokuthutha, esetshenziswa kabanzi emafektri, ezindaweni zokugcina izimpahla, ezitolo ezinkulu nakwezinye izindawo.Yenziwe ngezinto zensimbi engagqwali ezinokumelana nokugqwala, ukumelana nemihuzuko kanye nesakhiwo esiqinile, esingahlangabezana nezidingo zokuphatha izinto ezindaweni ezahlukahlukene.

-

Ngokwezifiso Umkhiqizi Wokwenza Ikheji Lensimbi Enkulu

Ukwakhiwa kohlaka lwensimbi enkulu ngokuvamile kuhilela ukusetshenziswa kwamashidi ensimbi aminyene, njengensimbi ne-aluminium, ukuze kwakheke izakhiwo zefreyimu ezinekhono lokuthwala umthwalo.Lawa mafreyimu avame ukusetshenziswa ezimbonini ezifana nezokwakha, i-aerospace kanye nokukhiqiza izimoto, lapho edlala indima ebalulekile ekusekeleni nasekuvikeleni.

-

Izingxenye zobakaki ezidumile zeshidi lensimbi ye-laser cut

Izinzuzo zokusika nokwenza i-laser yensimbi ikakhulukazi zifaka:

Ukunemba okuphezulu: ukusika kwe-laser kungafinyelela ukusika okuphezulu, iphutha elincane, izinga lokucubungula elizinzile nelithembekile.

Ukusebenza kahle okuphezulu: ijubane lokusika i-laser, lingasika ngokushesha izinhlobo ezahlukahlukene zeshidi lensimbi, lithuthukise ukusebenza kahle kokukhiqiza.

Ingakwazi ukusika amajamo ayinkimbinkimbi: ukusika kwe-laser kungasika amashidi ensimbi ezinhlobonhlobo eziyinkimbinkimbi, njengokuyindilinga, i-arc, izimo ezingajwayelekile, njll., ukuze kuhlangatshezwane nezidingo ezihlukahlukene zokucubungula.

Ikhwalithi enhle yokusika: ukusika kwe-laser kuyisicaba futhi kubushelelezi, asikho isidingo sokucutshungulwa kwangemuva njengokugaya, okonga izindleko nesikhathi.

Ukuvikelwa kwemvelo: inqubo yokusika i-laser ayikhiqizi noma iyiphi imfucuza, i-exhaust nokunye ukungcola, kuyindlela yokucubungula imvelo. -

Isakhiwo sensimbi ye-OEM design metal fabrication welding welding custom metal processing with laser cutting steel stainless table frame

Sisebenzisa izinto zensimbi engagqwali zekhwalithi ephezulu, ngokucubungula insimbi yeshidi elihle nokupholisha, ukuze sakhe uhlaka lwetafula oluqinile, oluhlala isikhathi eside futhi oluhle.Ungakhetha izitayela ezahlukene, osayizi kanye nemibala ukuze ivumelane nosayizi abahlukene bedeskithophu nezidingo.

-

Ishidi lokunemba eliphezulu elenziwe ngezifiso lensimbi yohlaka lomlenze wetafula lensimbi engagqwali

Uhlaka lwetafula lensimbi engagqwali luwuhlaka oluqinile futhi oluqinile lwesakhiwo setafula elihle futhi elisebenzayo.Insimbi engagqwali imelana nokugqwala, iqinisekisa impilo ende yesevisi.Ngobuchwepheshe bokucubungula insimbi yeshidi, amafreyimu etafula anobunjwa obuhlukene nosayizi angenziwa ngokwezifiso ngokuya ngezidingo, afanele izikhathi ezahlukahlukene.Ithoni esiliva-emhlophe kanye nomklamo olula wensimbi engagqwali yenza kube lula ukuhlanza nokugcina, ukuthuthukisa ubuhle bendawo yonke.Kungakhathaliseki ukuthi ihhovisi lezohwebo, impilo yasekhaya noma inkambu yokukhiqiza izimboni, uhlaka lwetafula lensimbi engagqwali luyisinqumo esihle.

-

Izivalo ze-chassis zeshidi zenziwe ngomshini futhi zenziwe kanjani?

Siyakwamukela esingenisweni sethu sefektri yangokwezifiso zeshidi lensimbi!Njengefekthri yokwenza ngokwezifiso zensimbi yeshidi, sihlinzeka amakhasimende ngezinsizakalo ezahlukahlukene zokucutshungulwa kwensimbi, okuhlanganisa nokwenza ngokwezifiso indawo ebiyelwe ye-chassis.

-

OEM inkambiso ongaphandle metal bike yokupaka iphrojekthi yokubeka

Lambert Precision Sheet Metal Processing Co., Ltd., with ten years of foreign trade experience, specializes in high-precision sheet metal processing parts, laser cutting, sheet metal bending, pipe bending, sheet metal chassis shell, power shell, etc., which can be applied to commercial design, ports, bridges, infrastructure, buildings, hotels, various pipeline systems, etc. Welcome to contact us by email: lambert@zslambert.com