Imikhiqizo

-

Amaphrojekthi Enziwe Ngokwezifiso Welding Yensimbi Izingxenye Zokwenziwa Kweshidi Lensimbi Engagqwali

Inqubo Yokwenziwa Kweshidi Ngokwezifiso Kuchaziwe

Inqubo yokucutshungulwa kwensimbi eyenziwe ngezifiso ngokuvamile ihlanganisa izinyathelo ezibalulekile ezilandelayo:

Ukuhlaziywa kwesidingo: okokuqala, ukuxhumana okujulile nekhasimende ukuze kucaciswe izidingo ezithile zebhokisi likagesi elibiyelwe, njengosayizi, ukuma, izinto ezibonakalayo, umbala nokunye.

Umdwebo Wokuklama: Ngokwezidingo zamakhasimende, abaklami basebenzisa i-CAD nenye isofthiwe yokuklama ukudweba imidwebo enembile ye-3D ukuze baqinisekise ukuthi yonke imininingwane ihlangabezana nezidingo zamakhasimende.

Ukukhethwa kwezinto ezibonakalayo: Ngokwezidingo zokuklama nokusetshenziswa, khetha ishidi lensimbi elifanele, njengensimbi engagqwali, i-aluminium alloy, njll.

Ukusika nokucubungula: Ukusebenzisa imishini ephezulu yokunemba njengomshini wokusika i-laser noma umshini wokusika amanzi we-waterjet, ishidi lensimbi lisikwa libe yisimo esidingekayo ngokusho kwemidwebo.

Ukugoba nokubumba: Ishidi elisikiwe ligotshwa ngomshini ogobayo ukuze lakhe isakhiwo esinezinhlangothi ezintathu esidingekayo.

Ukushisela nokuhlanganisa: Inqubo yokushisela isetshenziselwa ukuxhuma izingxenye ndawonye ukuze zakhe igobolondo lebhokisi likagesi eliphelele.

Ukwelashwa okungaphezulu: Ukwelashwa kwendawo ebiyelwe, njengokufafaza, ukuqhunyiswa kwesihlabathi, i-anodizing, njll., ukuze kwandiswe ubuhle nokuqina kwayo.

Ukuhlolwa Kwekhwalithi: Ukuhlolwa kwekhwalithi okuqinile kuyenziwa ukuze kuqinisekiswe ukuthi ubukhulu, ukwakheka nokubukeka kwegobolondo lebhokisi likagesi kuhlangabezana nezidingo zekhasimende.

Ukupakisha nokuthunyelwa: Ekugcineni, ukupakisha nokuthunyelwa kumakhasimende.

Yonke inqubo inaka imininingwane nekhwalithi ukuze kuqinisekiswe ukuthi umkhiqizo wokugcina ungahlangabezana nezidingo ezahlukahlukene zamakhasimende.

-

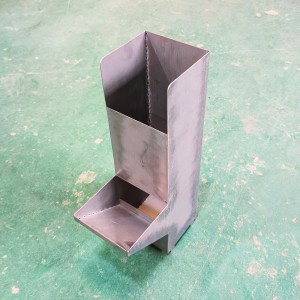

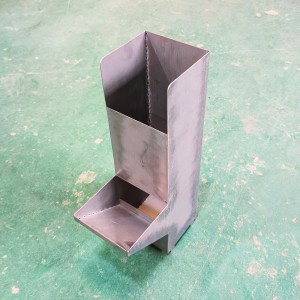

Ishidi lensimbi langokwezifiso elisebenza isitsha sesilwane esifuywayo sensimbi engagqwali engama-316

Izitsha zezilwane ezifuywayo zensimbi engagqwali eziyi-316 ezenziwe ngezifiso zezilwane zakho ezifuywayo, ezenziwe ngensimbi engagqwali yezinga eliphezulu, eziphephile futhi ezinempilo, ezikwazi ukumelana nokugqwala futhi zihlala isikhathi eside, ukuze isilwane sakho sijabulele ukudla okunethezekile.Sinaka yonke imininingwane ukuze sidale impilo emnandi yesilwane sakho osithandayo.

-

Isevisi ye-OEM Custom Stainless Steel Pipe Metal Welding Processing Service

Ishidi lensimbi yokushisela inqubo evamile yokuhlanganisa esetshenziselwa ukuhlanganisa izinto zensimbi ezincanyana njengensimbi namashidi e-aluminium.Eshidini lensimbi yokushisela, ithoshi lokushisela livame ukusetshenziselwa ukushisisa izingxenye zensimbi zibe yisimo esincibilikisiwe, bese izingxenye ezimbili zensimbi zihlanganiswa ndawonye ngento yokugcwalisa.Kunezinhlobo ezahlukene zokushisela i-sheet metal ezifana ne-spot welding, i-gas welding kanye ne-laser welding.I-Spot welding yenziwa ngokubeka izingxenye ezimbili zensimbi phakathi kwama-electrode amabili kanye nokusebenzisa amandla kagesi ukuze kukhiqizwe ukushisa okuphezulu ukuze kuncibilike insimbi ngokushesha futhi ibone ukuxhumana.Ukushisela igesi kwenziwa ngokushisisa izingxenye zensimbi ngelangabi nokwengeza izinto zokugcwalisa ukuze kubonakale ukuxhumana.Ukushisela nge-laser ukusetshenziswa kwemishayo yelaser enamandla amakhulu ukushisa insimbi ngokushesha ukuze kuqedelwe ukushisela.Ngokuthuthuka kwesayensi nobuchwepheshe, imishini yokushisela ezenzakalelayo namarobhothi asetshenziswa kabanzi ekushiseleni insimbi, ukuthuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yokushisela.Futhi ngokuthuthuka okuqhubekayo kwezinto zokushisela kanye nemishini, ubuchwepheshe bokushisela i-sheet metal buyavela futhi buba yingxenye ebalulekile embonini yokukhiqiza.

-

Ukukhiqizwa kwe-chassis ye-aluminum yeshidi langokwezifiso

I-aluminium chassis, ubuciko beshidi lensimbi, ukukhanda ngokwezifiso.Ukusebenza okuhle kakhulu kokukhipha ukushisa, ukuvikela ukusebenza okuzinzile kwemishini.Idizayini yobungcweti, ukwenza ngokwezifiso komuntu siqu, ukuze kuhlangatshezwane nezidingo zakho ezihlukile.Imininingwane inquma ikhwalithi, sakha yonke imininingwane ngekhanda.

-

Isevisi yokugoqa yensimbi engagqwali yensimbi engagqwali

Insimbi engagqwali ebiyelwe kagesi, iqinile futhi ihlala isikhathi eside.Sigxila ekucubunguleni ngokwezifiso zensimbi ukuze sihlangabezane nezidingo ezihlukahlukene futhi sinikeze isevisi yekhwalithi.Ubuciko obuhle kakhulu, ukulawula ikhwalithi okuqinile.Akugcini nje ukuthuthukisa ukuphepha kwemishini kagesi, kodwa futhi ubonise ukunambitheka kwakho nesitayela.

-

ishidi lensimbi ebiyelwe izixazululo zesevisi yokwenziwa kwezimboni eziningi.

Ukucutshungulwa kweshidi lensimbi ebiyelwe kuyinqubo ebalulekile yokukhiqiza ehlinzeka ngokuvikeleka nokubukeka kobuhle ezinhlobonhlobo zemishini nemishini.Insimbi engagqwali, njengeyona nto eyinhloko yokusetshenziswa, isetshenziswa kakhulu ekwenzeni ama-casings ensimbi futhi ithandwa ngenxa yokumelana nokugqwala, amandla aphezulu, nokuhlanza kalula.Ukuze kuthuthukiswe ukusebenza okunqanda ukugqwala kwegobolondo lensimbi engagqwali, ukwelashwa okungaphezulu okufana ne-anodizing, ukufakwa kwe-galvanizing noma ukufafaza ungqimba oluyisivikelo kungafinyelelwa.Ngasikhathi sinye, ubuchwepheshe bomshini wokunemba bubalulekile ekukhiqizeni ama-casings ensimbi enziwe ngokwezifiso ukuze kuqinisekiswe ubukhulu obunembile kanye nekhwalithi ezinzile.Noma ngabe okokusebenza kwe-elekthronikhi, okokusebenza kwezokwelapha noma okomshini, amabhokisi ensimbi enziwe ngokwezifiso angaklanywa futhi akhiqizwe ngokwezidingo zamakhasimende ukuze ahlangabezane nezidingo zezimboni ezahlukene kanye nokusetshenziswa.Ngakho-ke, ukucubungula kwezindlu zensimbi ngokwezifiso, njengobuchwepheshe bokukhiqiza okuyisisekelo, akugcini nje ukudlala indima ebalulekile emkhakheni wezimboni, kodwa futhi kuzoqhubeka nokuba nokubaluleka okukhulu ekuthuthukisweni kwesikhathi esizayo.

-

Custom sheet metal ebiyelwe ngensimbi engagqwali ibhokisi likagesi

Amabhokisi kagesi ensimbi engagqwali, amamangelengele futhi ahlala isikhathi eside, anikezela ngezinsizakalo zokwenziwa kwensimbi yangokwezifiso okokusebenza kwakho.Ukwamukela ukwelashwa okuhlukile kokugqwala ukuze uqinisekise ukuthi ibhokisi likagesi lihle njengelisha isikhathi eside.Ukusebenza okuhle kokukhipha ukushisa, ukuvikela ukusebenza okuzinzile kwemishini.

-

Isevisi ye-OEM yensimbi yensimbi yokugoba kanye nenkonzo yokushisela

Ngokwenza kwethu amashidi ensimbi angokwezifiso, sisebenza ngokukhethekile ekubumbeni izindawo ezivalekile zensimbi ezenzelwe wena.Idizayini yomuntu ngamunye, ubuciko obunembayo, ukubaza yonke imininingwane ukuze kuqinisekiswe ikhwalithi ephezulu.Sithembe ukuthi sizonikeza umkhiqizo wakho intelezi yensimbi emangalisayo futhi sakhe ikusasa eliqhakazile ndawonye!

-

Insimbi engagqwali eyenziwe ngokwezifiso yebhokisi likagesi leshidi lokucubungula insimbi

Ngokugxila embonini yokucubungula ngokwezifiso zeshidi lensimbi, sikunikeza izixazululo zamabhokisi kagesi ensimbi engagqwali ephakeme kakhulu.Inkonzo yethu ayibonakali kuphela ekukhethweni kwezinto eziphezulu kanye nobuciko obuhle kakhulu, kodwa futhi ilele kuyo yonke inqubo yenkonzo yomuntu siqu engenakukhathazeka.

-

OEM inkambiso ishidi metal steel kagesi ibhokisi yokukhiqiza

Sinikeza isevisi yebhokisi likagesi elisezingeni eliphezulu nelisezingeni eliphezulu lephrojekthi yakho!Ukusebenzisa izinto ezisezingeni eliphezulu ukuqinisekisa ukuthi ibhokisi likagesi ngalinye lensimbi libalwa ngokunembile futhi lenziwe.

Ngomklamo oyingqayizivele kanye nobuciko obuhle, ibhokisi lakho likagesi lensimbi ngeke ligcine ngokuphepha futhi liqinile, kodwa futhi lizoba okuvelele kwesikhala. -

Ikesi le-laser elenziwe ngokwezifiso leshidi lensimbi yokwenziwa

Izivalo zensimbi yensimbi engagqwali zihlanganisa ubuhle bezimboni nokuqina ukuze zikunikeze ukuvikeleka okumangelengele kokokusebenza kwakho.Sikhetha izinto zensimbi engagqwali ezinhle kakhulu futhi sisebenzisa ubuchwepheshe obuthuthukisiwe bensimbi ukuze senze ngokwezifiso noma imuphi usayizi noma idizayini oyidingayo.

-

Iyini i-Sheet Metal Fabrication Engineering

Iyini i-Sheet Metal Fabrication Engineering

Ubunjiniyela bokucutshungulwa kwensimbi yeshidi bubhekisela kunqubo ebanzi yokusebenza ebandayo yamashidi ensimbi amancane (imvamisa engaphansi kuka-6mm), okuhlanganisa ukugunda, ukunyathela, ukugoba, ukushisela, ukugoqa, ukuhlanganisa, ukubumba nezinye izinqubo ukuze kukhiqizwe umumo nosayizi oyifunayo.Lolu hlobo lokucutshungulwa lusetshenziswa kakhulu ezimbonini zokukhiqiza ezifana nezimoto, ezondiza, eze-electronics nezinto zikagesi.Isici esihlukile sokucutshungulwa kwensimbi yeshidi ukuthi ubukhulu bengxenye efanayo buhambisana futhi buhlala bungashintshile ngesikhathi sokucubungula.Ukucutshungulwa kwayo ngokuvamile kuhlanganisa izinyathelo ezifana nokugunda, ukugoba, ukugxiviza, ukushisela, njll., futhi kudinga ulwazi oluthile lwejiyomethri.Imishini yokucubungula insimbi yamashidi ikakhulukazi ihlanganisa umshini wokunyathelisa wensimbi, amasheki nezibhakela neminye imishini nemishini yenhloso evamile, isikhunta esisetshenziswayo singamamodeli amathuluzi alula futhi asebenza emhlabeni wonke kanye nesikhunta esikhethekile sezinto zokusebenza ezikhethekile ezinokubumba okukhethekile.Ibonakala ngezinqubo ezigxilile, izinga eliphezulu lemishini kanye nokukhiqizwa okuzenzakalelayo okulula ukukubona.Enqubweni yokucubungula insimbi yeshidi, ukunakwa kufanele kukhokhwe ekukhethweni kwezinto ezibonakalayo, ukuklama inqubo, ukulawulwa kwekhwalithi nezinye izici.

Sengiphetha, ubunjiniyela be-sheet metal processing uhlobo lobuchwepheshe bokucubungula amapuleti ensimbi amancane, abonakala ngokunemba okuphezulu, isisindo esilula, ukuhlukahluka nokusebenza kahle okuphezulu, futhi angahlangabezana nezidingo zemikhakha ehlukene.